Machine components for conveyor systems in the new port terminal Porto Sudeste/Brazil

VULKAN Drive Tech, a division of the VULKAN

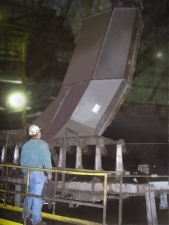

Group, is specialized in designing, manufacturing and delivering of mechanical power transmission and braking systems for bulk material handling equipment and machinery. The latest project involves VULKAN as a major player in the new port terminal of Porto Sudeste, in the Sepetiba bay, about 80 km from Rio de Janeiro (Fig. 1). The terminal is going to cover an area of more than 52 hectares and will be able to handle up to 100 mill. t iron ore per year. The terminal will be mainly used to export iron ores of the state Minas Gerais and will start operating within 2012.

VULKAN has been contracted to supply backstops for the conveyor belt systems of the whole terminal area, including the four stacker-reclaimers which operate as primary moving machinery. The conveyor belts have a total length of more than 4000 m, a load capacity of 12 000 t/h and a speed rate of 5 m/s. Such transportation capacity needs adequate safety and control devices. Backstops are an indispensable safety element. They prevent the load falling backwards if the drive system fails, for example during a power cut. The large mass of the conveyed load would be uncontrollably accelerated backwards owing to the gravitational force of the conveyor. If no backstop is used, the consequences can be immense. Damage to the expensive drivetrain is not even the biggest problem. The costs of the unscheduled machine failure and the downtime of the plant are usually much higher. For these reasons, at the Porto Sudeste project, the installation of VULKAN Drive Tech backstops onto uphill conveyor belts prevents the load of iron ore falling backwards in the unlikely event of the drive system failing.

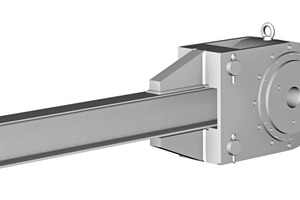

By taking into account the belt conveyors’ length, elevation and load capacity, speed and operating conditions, VULKAN Drive Tech is able to engineer the most suitable backstop solution for the conveyor at the Brazilian port terminal to guarantee the systems functionality and safety on site. VULKAN Drive Tech backstops can be applied to either high-speed or low-speed shafts (Fig. 2). They consist of cylindrical rollers positioned between an external ring and a ramp surface on the internal hub. Pressure springs act on pins, which force the contact of the rollers simultaneously on the external ring and on the ramp surface, assuring the necessary backlash-free blocking. Depending on the application requirements and design, VULKAN Drive Tech backstops can also be equipped with internal bearing systems. Furthermore custom finishing of the shaft connection, torque arms in different design and length, oil reservoir for continuous lubrication, are only a few of the possible customization options VULKAN Drive Tech offers to its customers.

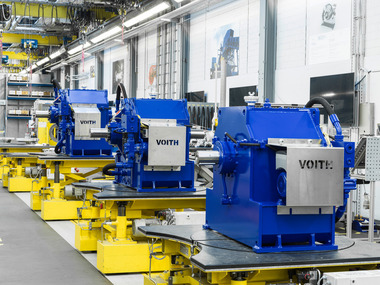

More than 40 different types of backstops have been designed and produced for the Porto Sudeste project, involving coordination of engineering and production activities in three different countries, between customer, VULKAN Sales Organizations and VULKAN Manufacturing Sites. VULKAN Drive Tech is present at 38 locations around the world, with production facilities and sales & service offices and provides on-site customer-oriented service worldwide.