Liebherr-Mischtechnik GmbH

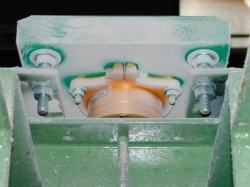

The mature technology of the Liebherr Litronic-FMS II moisture measurement system (Fig.), consisting of sensor, evaluation electronics, and software is in use all over the world – and is a huge success. Possibilities range over the most widely differing types of bulk goods. In these situations, too, the sensors can be installed on belts and slides, at transfer points, in silo outlets, dryers, pipelines, containers, and all kinds of other locations. The „intelligent“ moisture sensor makes the system the ideal measuring device for the exact determination of the moisture content in the ongoing process. This makes it possible to monitor or even correct a production process so as to ensure the formulation is right. The arithmetical mean value is determined over the entire metering period by the integrated microprocessor. The moisture content in the medium is measured in real time. Another major advantage is that if a sensor is replaced, no recalibration is required, because the sensors are designed to be fully reproducible. The FMS-II software displays all the functions at a glance on the screen, and the most widely differing range of interfaces makes connection to many process control systems simplicity itself. Parametering can also be carried out optionally by means of an additionally available pocket PC and Bluetooth adapter.