Winter operations

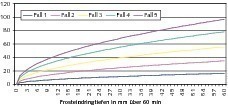

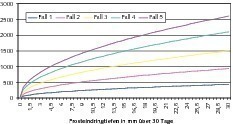

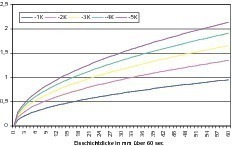

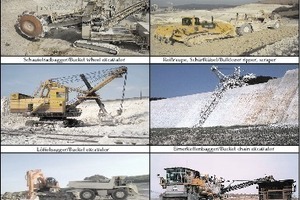

Theses on mining of chalk at low temperaturesSummary: Of all the forms in which limestone occurs, chalk possesses the highest level of natural moisture. This may vary between and 18 and 23 %, depending on the proximity of the groundwater table in the vicinity of the deposit. Under open-cast quarrying conditions, the moisture content of the raw product can even increase to significantly above 25 %, depending on meteorological conditions and the extraction method used. In the extraction and transportation of chalk using open-cast methods, prolonged freezing weather causes difficulties which may range from reduced production and increased operating costs up to and including seasonal discontinuation of extraction operations. Therefore it is necessary to identify the essential factors influencing safe and reliable mining of chalk under winter conditions, in order to be able, on this basis, to select suitable methods more systematically than has been possible up to now.

1 Introduction

The extraction and preparation of chalk necessitate an approach different to that of the customary industrial standard for production of cement [1]. In the extraction and transportation of chalk using open-cast methods, prolonged freezing weather causes difficulties which may range from reduced production and increased operating costs up to and including seasonal discontinuation of mining operations [2].

There are extensive chalk mining regions in Eastern Europe (Fig. 1). A large range of diverse activities for the modernization of existing and the creation of new capacities are...

![Model of the semi-infinite body (for 0 ≤ x ≤ ∞) after [3]](https://www.at-minerals.com/imgs/tok_35af95dc3eca92b1da89eac95974e0b7/w228_h200_x114_y107_101295478_769b2778fe.jpg)

![Plot of temperature during freezing of a flat solid body, after [6]](https://www.at-minerals.com/imgs/tok_0a947d93801f8419d4f55edf2dca467d/w233_h171_x116_y85_101295447_24d6426898.jpg)

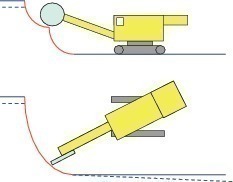

![Mobile slurrier concept for oil sand [7]](https://www.at-minerals.com/imgs/tok_c1da1173e9fc33f0ebd2aa3085142396/w300_h158_x282_y79_101295457_9467f1d3a2.jpg)