Skako Vibration modernizes coarse and wet screening plant

Skako Vibration, a company based in Alsace, was contracted by Carrières du Boulonnais in Ferques/Northern France to realize two projects, involving the replacement of the one of its two coarse screens as well as two wet screens in its pre-screening station. The difficulty involved with this contract was installing the machines and associated equipment in place of the old machines without making any changes to the existing facilities. The replacement was completed without any unforeseen occurrences in the first two weeks of August 2010.

At this stage of processing, the clay content (0/200) is recovered from the material extracted (0/2000) on the SC603 coarse screen, from where the material is conveyed to the washing equipment. The residue is crushed in a jaw crusher, with a throughput rate of 1000 t/h, at a gap width of 2000 mm and a discharge of 0/400 mm (size reduction ratio of 5). The throughput rate of the screen now totals 2500 t/h, whereas originally, in the year 1991, it totalled 1800 t/h. On account of this production increase, the company wanted to replace the existing machine. According to the contract specifications, the operator also required an option for feeding blocks up to 5 t to the first stage of the coarse screen, i.e. up to 2 m3 in size (0/2000), which fall from a height of 50 cm. To ensure the required throughput rate and enable processing of the specified block size, it became necessary to install a new machine with a high capacity and particularly rugged design.

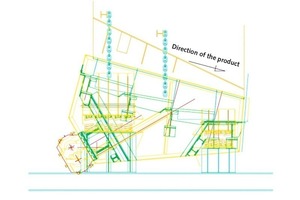

To meet these requirements, Skako Vibration proposed an FGD grizzly screen with a width of more than 2400 mm, a length of almost 5 m and a weight of 25 t, equipped with two DS7 exciters, which are powered by a 75-kW motor (Fig. 1). With these two exciters, the vibration system is powerful enough to drive the coarse screen to match the limestone feed rate. The machine guarantees a throughput rate of 2000 t/h with peaks of 2500 t/h.

Even if the dimensions of the coarse screen with its three screening surfaces are similar to those of the dismantled machine, “the differences are in the detail,” explained Stéphane Renault, project manager at the screen manufacturer. He continued, “The carrier support of the first stage is fitted with a section designed by Skako; it can withstand any falling blocks.” Frédéric Lavier, the man in charge of new installations and improvements at Carrières du Boulonnais, reports further: “The carrier support in the old design consisted of a metal cross bar, the durability of which was a cause for concern with regard to absorbing impacts. Its fastening points had to be regularly checked.” Another aspect that had to be changed was the static jaws. “They extended very far inside the machine and deformed as a result of impact of large blocks, subjecting the vibrating coarse screen to friction,” recalls Frédéric Lavier. These static jaws were replaced with shorter guide jaws and the wear bars raised. Now the coarse screen itself channels the feed material.

The installation described, equipped with new spring support brackets (Fig. 2), lends greater stability to the machine and eliminates primarily any vibrations in the structure. It also enables damping of the vibrations transferred into the interior of the building. The suspension brackets of the new coarse screen are attached to the rigid points of the machine to avoid deformation.

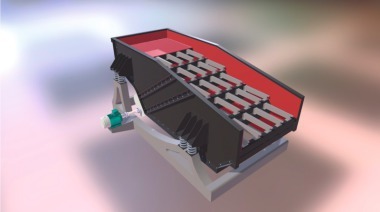

At the feed side, the coarse screen is supported on five springs (Fig. 3). These parts are not as rigid as buffers, even if these absorb the dynamic and static forces better, but Skako Vibration has modelled the load on these springs and incorporated a safety margin based on the installation of more parts than necessary.

The series of vibration measurements conducted after the work had been completed showed that commissioning of the new coarse screen had effected a dampening of the unwanted vibrations transferred to the structure of the pre-screening station. The coarse screen equipment consists of grids made of Hardox steel 450 with a thickness of 60 mm (Fig. 4). These three grids have a considerable weight of 6.6 t, compared to the 25 t of the machine. Their cascade arrangement (with 15°, 10° and 5°) and their apertures (from 170 to 200 mm) prevent screen blinding.

With regard to wear of these screening surfaces, the view in Ferques is that it is not a serious factor, although it should not be neglected. After all, the limestone of the Boulonnais is hard and less abrasive in the dry state. During wet processing, however, the fines do result in wear during screening. To gauge the lifetime of these grizzly surfaces, the operator must take the given impact effects into consideration.

The coarse screen is designed to start up under load, to cater for all operating states, “but the processing operation does not allow for this case.” admits Frédéric Lavier. “This machine is put into operation at the start of the shift and switched off at the end of the day, after the second shift.” To stop the machine, Skako Vibration has had a braking controller installed, as on all vibrating screens commissioned by Skako at this plant. The principle of this electronic brake is to generate a strong braking torque with the help of a rugged converter, in combination with stress-free numeric electronics. Here the braking effect is generated by applying direct current to the winding of the motor so that a magnetic induction field brakes the revolution of this motor. “The motor of the coarse screen is therefore braked in 2 seconds from 750 to 0 rpm, which is pretty amazing,” says the operator. “If the machine reaches a frequency between 200 and 300 rpm, it starts to move strongly, but, thanks to the brake controller, it has no time to start resonating.”

According to the manufacturer, the brake switch is a modest investment, which, however, can put the operator’s mind at ease with regard to the vibrations transferred to the structure of a building. Its installation does indeed limit the effects of resonance in the shutdown phases and therefore the dynamic loads generated by the machine, which are always very strong during these phases. The coarse screen does not need any control. The only settings concern the mesh width with changes in the gap width in order to control separation efficiency.

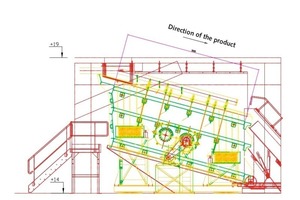

With regard to the two wet screens, there was an urgent need for action. Following their commissioning in 1994, their mechanical condition and the condition of the springs required excessive maintenance: “The sidewalls were extremely worn and there were problems with leak-tightness around the mechanical drive, leading to the ingress of water,” explained the operator. On failure of this critical equipment, the coarse screen had to be shut off as the screens were installed at the discharge outlet of the washing drums. They are fed with a 0/200 fraction from which any sand and clay have been removed. Skako Vibration installed two new identical wet screens of the type S3S in place of the old machines (Fig. 5). These big screens with circle diagram measure 2000 mm in width, 5000 mm in length and have a wall height of 2500 mm. Each weighing 14.5 t, they comprise three stages (mesh width 100x100, 80x80, 70x70) whereas the original machines had 3.5 stages. The screens consist of welded screening surfaces with flat square mesh and cut-points at 105, 80 and 65 mm.

In his scope of supply, the manufacturer has made certain changes compared to the old screens, which are based on the experience of the operator, and especially of the maintenance department. Worth mentioning is the receiver deck for the feed to protect the screening surfaces against impact. Sealing of the mechanical drive (with grease) was also reengineered with the installation of guide plates to protect the through shaft. The same applies to the walls and distance tubes. As another new feature, the rolling bearings were chrome-plated.

The screens are wet screens with built-in static and dynamic spray jets that spray water onto all the bridges. Their screening rate is on par with that of the machines they replaced. The speed of the screens achieved with two mechanical drives (necessary because of the respective screen weights) is 660 rpm, with an amplitude of around 0.7 cm and a stroke of 1.4 cm. “The amplitude is, of course, larger than that of the earlier machines to protect against blinding of the screening surface with a mesh width of 105 mm,” explains Stéphane Renault.

To prevent water containing fines flowing between the inner struts of the screen and the wall (causing wear of this plate), Skako Vibration has fitted rounded-edge plates to the wall. The water now flows into the screen. The 5-m-long struts consist of several elements to avoid the installation of one single part, which would have the disadvantage of causing the water to flow.

With regard to wear, Skako has supplied a machine with improved protection, especially at the intermediate deck, the lower deck, the cross bars, the discharge nozzles and the vertical surfaces. The screens are metallized with pure zinc and not galvanized as “owing to this process, sometimes large reinforced parts, like walls, become deformed,” Stéphane Renault adds. A special feature of the screens is the high wall height between the bridges, 760 mm and 1100 mm, so that technicians have no problem climbing in to do maintenance work (Fig. 6). The screens were designed for a screening rate of 675 t/h per machine. This is a much higher capacity than that of the old equipment.

The success of this project was only possible thanks to the good cooperation between the different departments of the client and the supplier. To realize this project, the new installation department called in both maintenance and manufacturing staff to draw up precise and “reliable” performance specifications. The technicians were also involved in the technical reworking of the project – a procedure that seems to be standard at Carrières du Boulonnais. Accordingly, the supplier knows which technical solution he should offer to meet the operator’s requirements. This sort of cooperation is ideal and at the same time provides an opportunity to broaden know-how – in the interest of the sustainability of the equipment.

The installation of the three machines in the first two weeks of August 2010 required the compilation of performance specifications on account of the lack of space. For the screens, a car had to be developed, which travels on three monorails; each screen was lifted flat with a crane into the building (Fig. 7), with two anchorage points on the machine. At the height of an opening in the building, the screen was fixed to the monorail and gradually moved into the station. For the dismantling of the old screens, aprons and bins as well as all associated parts and the cut-out of part of the concrete floor, during the entire downtime of the machines, work was done in three shifts.

Jean-Pierre Le Port (mines & carrières, janvier 2011, p. 28-31)