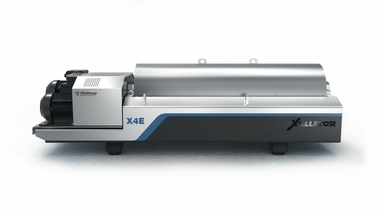

Two innovations from Flottweg

There is no clean water without efficient wastewater treatment. Solid bowl centrifuges, so-called decanters, play a major role in our sewage plants during wastewater treatment. Centrifugal forces within the decanter provide the best possible separation of solids from water. Specifically for this task, Flottweg has developed the new environmental centrifuge C7E (Fig.). With the help of this high-performance decanter, up to 160 000 l of municipal sewage sludge can be processed per hour. For sewage plant operators, efficient thickening and dewatering are prerequisites for cost-efficient disposal, incineration or landfilling. The new C7E decanter centrifuge has been specially developed to fulfil the strict requirements of wastewater treatment. In addition to its excellent high clarification and separation efficiency, the decanter sets new benchmarks for energy efficiency and process stability. This can be achieved with the centrifuge’s special design features: the intelligent relationship between the clarifying field and the pond depth, as well as the SIMP-DRIVE® system.

In order to save even more energy during centrifugal wastewater clarification, Flottweg has developed the RECUVANE®-System. Energy is required to process the sewage sludge in the centrifuge. The suspension is accelerated to the rotational speed of the centrifuge, thus separating the water from the solids. Normally the clarified water is discharged via weir plates, without recovering the energy from the water. At this point the RECUVANE®-system comes into play. With this mechanical system, the discharged centrate water helps to power the main drive of the centrifuge using the energy which is still contained in the water. With this it is possible to reduce power consumption up to 20 %. This system in the Flottweg wastewater decanters can, similar to weir plates, be upgraded quickly and easily.