Improved Grinding

CEMTEC‘s Research & Development capabilities, focusing on the example of the vertical mill

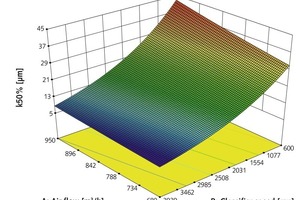

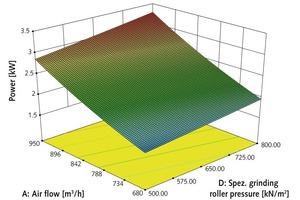

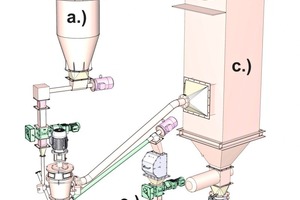

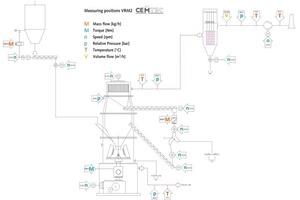

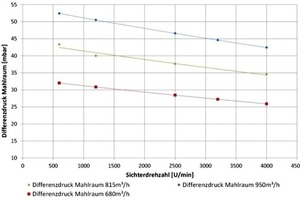

Summary: The production of mineral products, which perform highly important functions in modern materials (“functional minerals”), of defined and usually extremely fine particle size distributions at minimized energy consumption, is playing an increasingly important role on the European market. In this field, the use of roller mills is a forward-looking technology. The necessary grinding parameters for these mills generally have to be determined with extensive test plans, in order to attain the required specifications under competitive conditions. Modern design of experiments and test evaluation assist in shortening this process, thus making it more cost-effective. Within this conflicting field, CEMTEC is working in co-operation with the Montanuniversitaet Leoben, to develop efficient process technology.

1 Introduction

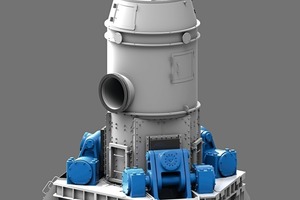

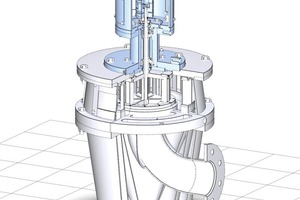

CEMTEC has been a supplier of grinding equipment and integrated plants in the mineral resources sector for more than twenty years. The fillers and extenders industry, which is important especially for the European market, has so far been supplied predominantly with ball mill and classifier technology. In 2008, the benefits of roller grinding, including a smaller installation footprint, comparatively high feed dispersity and reduced specific energy consumption, provided the incentive for the company to expand its product range to include vertical roller mills. An innovative drive...

![7 Half Normal Plot für k50% [Abszisse: Effektbeträge - Ordinate: kumulierte Häufigkeit] ● Half-normal plot for k50% [Abscissa: effect amounts - Ordinates: cumulative frequency]](https://www.at-minerals.com/imgs/tok_8dbaccf1a28fa1f536174f37e96fb221/w300_h200_x400_y330_101290489_4c7b1deaf3.jpg)