Efficient and eco-friendly

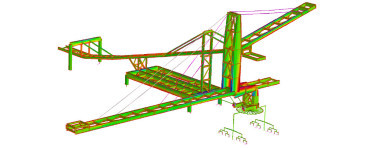

Tenova TAKRAF Italy has been awarded a contract by ILVA S.p.A. for the design and supply of a bucket-chain continuous ship-unloader (CSU) for handling iron ore and coal at the ILVA steel plant in Taranto/Italy. This plant is the largest of its kind in Europe (Fig.). The 18-month turnkey contract builds on a long-standing business association between Tenova TAKRAF and ILVA of over 40 years. The new CSU in Taranto will be almost entirely manufactured by Italian companies and is expected to be operational in late March 2015.

Following the devastating tornado of November 2012, ILVA initiated a plan for environmental rehabilitation of the steel industry in Taranto. The new CSU was ordered as a consequence of this. The plan involves replacement of the old grab ship-unloaders at the ILVA plant’s Pier II with modern bucket chain CSUs, which significantly reduce dust emission during the discharge cycle. The CSU’s low environmental impact is a major feature, noting that the steel plant is close to the city area. The new CSU will have an operating capacity of 4000 t/h for iron ore or 2240 t/h for coal and will be able to download vessels up to 150 000 tdw (deadweight tonnage). The CSU will be erected on the existing runways to feed the entire steel plant with coal and iron ore and pellets, together with the other machines at the plant.

//www.takraf.com" target="_blank" >www.takraf.com:www.takraf.com