Environmental friendly way to dispose of tailings from mining industry

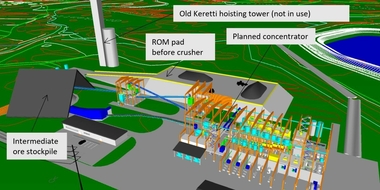

Outotec is one of the few companies in the world that can offer paste thickening solutions to the mineral industries in one package. Paste technology means that instead of pumping untreated tailings from the concentrator into tailing ponds, the sand is dewatered to a point when it does not segregate as deposit (Fig. 1).

Outotec’s expertise regarding paste technology springs from the company’s long experience of minerals and metals processing technology. “Using paste technology the tailings form a conical pile and do not need big ponds to be stored in. This means that the disposal area is much smaller compared to conventional tailing ponds and the danger of leakage is minimal”, explains Anders Nyström, Technology Sales Manager of Paste and Backfill Solutions at Outotec. Anders Nyström got in touch with paste technology when he was leading a project aiming at minimizing the area needed for tailings disposal at a mine in Canada in 2002. “The mine was not allowed to extend the tailing ponds but could use the existing tailing pond by placing the paste tailings on top of the existing tailings. This was possible only by using paste technology.”

The mining industry faces growing challenges globally on how to use water efficiently, how to recover and recirculate water and how to reduce the areas needed for tailings storage. “That’s why the market for new sustainable solutions for tailings treatment is growing”, says Nyström. “Since the water from the tailings is efficiently recovered using paste technology, the water can be used over and over again. This makes the technology attractive especially in dry regions.” In addition the paste technology makes it much easier to restore the landscape in a safe way after a mine is closed. “We are now investigating the possibility with adding fertilizers and seed to the tailings through the paste plant some time before the mine will be closed down. This way the restoration process needs very little extra work. By using this method the closure process can be started in good time, saving time and money and in an environmental way improving the closure process.”

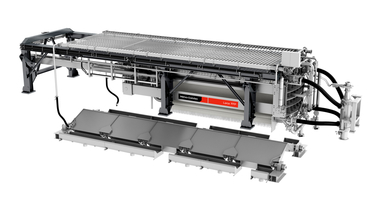

With the recent acquisition of the Australian company Backfill Specialists, Outotec can now offer even more comprehensive tailings treatment solutions to mining industry worldwide. “Paste backfill is mainly used to stabilize underground excavations, says Mathew Revell, head of Outotec’s Paste and Backfill Solutions business. “It means that a mix of paste and cement is pumped into previously mined stopes to form a rock solid material.” The paste backfill supports for example the walls of adjacent adits as mining progresses (Fig. 2). “This way the mine can be utilized to a maximum since it makes it possible to mine all of the ore deposit,” Mathew Revell explains. “The paste backfill can also serve as a working platform in a mine. In short, by using paste backfill the mines can be utilized more efficiently and above all, safely.”