Filter technology meets stone technology for optimized treatment of process water

Jogerst Steintechnologie works and shapes natural stone for a wide range of applications. Working stone is associated with a high input of process water. An effective and efficient treatment of the waste water and a drastic reduction in the addition of fresh water was a declared aim of the company. But the new filter system had to manage in the space that the existing system of sedimentation tower and chamber filter press for sludge dewatering – now quite old and reaching the limits of its capacity – had available. With the filter system comprising lamella separator for sedimentation and a vacuum belt filter (VBF) for further dewatering from Leiblein, the filter specialist, optimum filtering performance has been achieved.

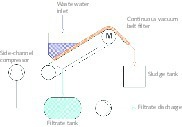

Starting from various collection points, the dirty water reaches a central collection pit and is fed depending on the level of the water to the lamella separator. In this lamella separator, sedimentation takes place so that the cleaned water flows over a gradient into the clear water pit for further use. Depending on the throughput rate and solids content, an added flocculant optimizes the sedimentation process. But that isn’t enough. The last residues of water of the materials that have sedimented in the lamella separator – contained there as thin sludge – have to be processed for the water circuit. Here the vacuum belt filter (VBF) does a formidable job. Dewatering is so effective that fresh water has to be added to the limited amounts of water adhering to the resulting filter cake.

The diversion of the dirty water from the inlet channel causes it to flow upwards through the lamella pack. On its way, the floating particles sink onto the inclined lamella (sedimentation) and slide into the sludge hopper. Even the smallest particles can be fixed with the addition of small amounts of flocculants and removed from the water. The filtered water is now ready for use in the process water circuit.

The downstream cleaning of the thin sludge in the vacuum belt filter substantially increases the recovery of cleaned process water. Here, Leiblein also relies on the principle of inclined levels and achieves optimum filter performance with the help of underpressure. The continuous belt made of stainless steel is designed as an inclined surface, the whole width of the lower part being submerged into the dirty water, while dewatering starts in the upper part. Dirt particles are retained by the filter belt, a firm filter cake builds up under the influence of slight underpressure. With the increase of the flow resistance initiated by this, the water level increases up to a level from which an integrated float switch controls the drive. With the pull-up of the filter belt, the layer of sediment is scraped off for further disposal. Then a brush roller and flushing system ensure a clean filter belt, ready for a new filter process.

The high filtering rate, a long lifetime because of the stainless steel filter as well as the absence of consumables and fully automatic operation without operatives lead with this filtration stage at Jogerst Steintechnologie to good results of the mechanical filter technology.

$(LEhttp://