Gravel plant in Austrian mountains with Leiblein water treatment system

In the Austrian state of Vorarlberg, between the Silvretta and Vermunt reservoirs, at around 1750 m above sea level, the Obervermuntwerk II pumped storage power plant is currently being built. It will be the second largest power plant owned by the energy supplier Vorarlberger Illwerke AG, with a power output of 360 MW in turbine and pump operation. With four building areas, its completion is now being pressed ahead.

The area with the largest temporary construction area at the foot of the dam wall is dominated by the towering silos of a mixing plant and a modern gravel plant to ensure environmentally compatible concrete production all year round (Fig. 1). After all, processing of the aggregates for the concrete from the excavated material accumulated on site was a key environmental requirement. So, for example, around 115 000 m³ cavern material and some rock excavated from 8000 m tunnels and 500 m shafts (around 250 000 m³ in total) could be used without any CO2 footprint of thousands of truck transports from the valley. At the same time, winter operation is assured.

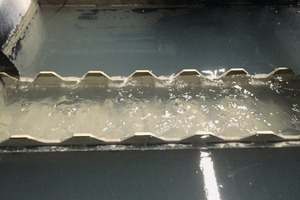

The compact gravel plant on account of the restricted space in the mountains combines a material processing plant as well as two concrete mixing plants. While the excavated rock assigned to the gravel plant is processed and washed via several crushing and screening stages and then, sorted by particle size, sent to interim storage, the mixing plants with the aggregates produce concrete of the highest quality. An environmentally friendly addition to the plant is the integrated water treatment system (Fig. 2). With this plant module from the filter specialist Leiblein, the process water for washing the rock is cleaned for reuse (Fig. 3).

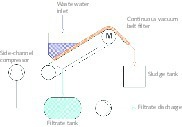

The product specifications stipulated a throughput rate of 280 m³/h, at a solids content of around 5 %. The particle size was defined mainly < 63 µm. After cleaning of the waste water from the gravel and sand washing, the process water was to be recirculated (Fig. 4), and the thin sludge then compressed to a dry material. To meet these requirements, the Leiblein technicians used a SK 300 lamella clarifier as well as a chamber filter press.

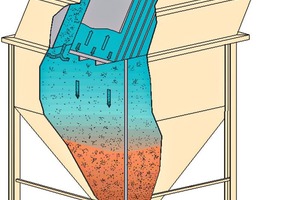

The lamella clarifier used removes particles > 50 µm as sediment, even smaller particles can be removed with the addition of flocculants, which can be optionally mixed into the water flow in a static mixer. After the dirty water is fed to below the inclined lamella pack and flow is reversed into an upwards direction, the particles sediment as they pass through the lamellae.

The collected sludge slides off the lamellae and is collected in the sludge hopper, from which it is removed at intervals with a sludge pump and sent via a sludge storage tank to the chamber filter press. A rabble rake for homogenization of the sediment and a sludge level measurement with the aim of removing the sediment from the lamella clarifier in as dry a state as possible, support the chamber filter press in dewatering the blanket of sludge to a dry filter cake. With the return of the filtrate into the water circuit via freefall into a pump receiver with further transport, there is limited water compensation with minimal addition of fresh water. This careful use of waste water and fresh water is a great benefit for the environment.

Thanks to the compact size of the plant, the Leiblein water treatment fits in seamlessly with the demand for space-saving structures with minimum impact on the natural surroundings. With its small dimensions, the filter plant could be integrated in a suitable building, which ensures operation at temperatures below zero without any problem (Fig. 5). With a view to the future, the Leiblein system has been designed to be semi-mobile. At the end of the construction period, the system can be transferred to another site or extended as required.