Loss-in-weight feeders with vibrofeeder

A central element in processing is the metering and weighing of bulk solids. In production processes, materials are fed and weighed at points where metering of the main components and additives with high accuracy is necessary. This precise metering is necessary, on the one hand, to ensure the quality of the resulting product and, on the other hand, to avoid metering of excessive quantities of expensive input materials. Such high accuracy is often required in the foodstuffs, pharmaceuticals and chemicals (fine chemicals, plastics manufacturing) industries.

For actual metering, different metering equipment is suitable. If the bulk solid consists of free-flowing material, loss-in-weight feeders are usually used. One reason for this is that high accuracies can be realized and another is that the bulk solids are conveyed in an enclosed area. Different types of loss-in-weight feeders are available depending on the discharge equipment. Here in addition to screws and belts, vibrofeeders are also used. For continuous, gravimetric and batch feeding of free-flowing bulk solids without hygroscopic, sticky or flooding properties, the vibrofeeder is always the best choice.

As the vibrofeeder, unlike screws and belts, does not impose shear and compressive forces on the bulk solids, it is the perfect discharge equipment for fragile (foodstuffs), abrasive (coarse-grained powders, pellets, granulate) or difficult-to-handle (fibres, glass fibres, pharmaceutical powders) bulk solids. The troughs are designed to be free of dead zones (quick and easy to clean) and the vibration drive is almost maintenance-free. Accordingly, the vibrofeeder within a loss-in-weight system is the perfect discharge unit in order to realize very gentle weighing (volumetric and gravimetric) with highly accurate and homogeneous feeding and high delivery rates. As, unlike other manufacturers, AViTEQdoes not buy in the feeder equipment, but makes it itself, AViTEQ can cater more closely for customer requirements and the product and offer the perfect Weiteq-brand loss-in-weight feeder.

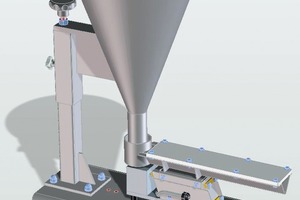

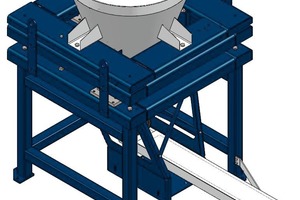

Apart from with regard to the discharge equipment, the Weiteq loss-in-weight feeders at AViTEQ can be divided into two categories. One the one hand, a standard model (Fig. 1) composed of existing AViTEQ components which are assembled as from a kit and on the other hand a customized model (Fig. 2). Basically, 70 % of customer requirements can be met with a standard model.

Operating principle of the loss-in-weight feeder

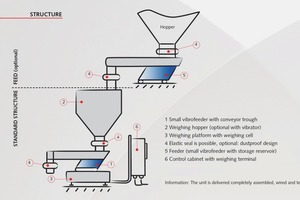

With the loss-in-weight system, the entire unit, that is the weighing hopper together with the content as well as the metering equipment including the drive unit are weighed and the loss in weight on metering of the bulk solids is measured (Fig. 3).

In operation, the AViTEQ small vibrofeeder (1) draws from the weighing hopper (2) a defined portion of the material as a defined delivery volume at a defined conveying rate. The operation of a loss-in-weight system is divided into the metering, refilling and settling phases. In the metering phase, the actual conveying rate and volume of material are measured continuously gravimetrically with a high-resolution weighing cell (3). The weighing control system (6) processes the values from the weighing cell against a defined set value and controls the conveying rate of the small feeder with the help of the AViTEQ Vibtronic control system. If the loss-in-weight feeder is used in batch mode, after the set delivery volume has been reached, the system deactivates conveying until the next release. Once the minimum required material level in the weighing hopper has been reached, the refilling phase begins. In this process, the upper feeder (5) is activated and the weighing hopper is refilled until the set maximum material level has been reached, followed by a necessary settling phase. In the refilling and settling phase, metering operates volumetrically.

One positive feature of loss-in-weight feeding systems is that variations of the bulk weight, changes in particle sizes or changing flow behaviour have hardly impact on material accuracy, as the material flow is monitored continuously based on weight and controlled.

A case study

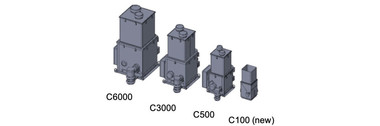

In a chemical plant in the Ukraine, washing powder is produced and packaged for a large manufacturer. The task for AViTEQ and its Weiteq brand was to accurately meter the additive (sodium tripolyphosphate) into the washing powder production process. Sodium triphosphate is a colourless sodium salt used in washing powder to soften water and support the effect of surfactants (Fig. 4). The additive used in production has a bulk density of 0.8-1.2 t/m³ and a particle size of 0.25-2.0 mm.

The customer specified metering accuracy of ± 0.1 %. The difficulty was to achieve this high accuracy both in long-term and short-term measurement. The requirements were met with a customized version (Fig. 5). Here besides the conveying rate of 50-1000 kg/h, the available installation space was taken into account. The scope of supply included frame, weighing hopper, vibrofeeder, weighing cell, pneumatic pusher and control system. The Weiteq WLW80/900 loss-in-weight conveyor was completely assembled, wired and tested and installed directly under the silo. The supplied pneumatic pusher is installed above the weighing hopper and is used as a closing element between the weighing hopper and silo. Accordingly, the pneumatic pusher constitutes the feeder during the refilling phase.

Hall 1, Stand 419

$(LEhttp://