Process water purification with the Leiblein scraper belt lamella separator with

gravity sedimentation in the smallest of spaces

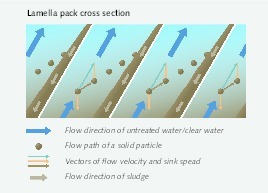

Intelligent water flow effects sedimentation of solids

The untreated water enters the inlet channel of this type of lamella separator and then flows slowly downwards where the flow is reversed and streams up through the lamellae. The particles and flocs sediment under the action of gravity, form sludge and slide into the sludge area. The upwards flowing clarified water flows over an overflow weir into the outlet.

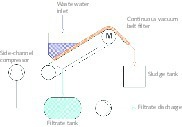

The scraper belt conveys the sludge continuously or in intervals upwards above the water level where it is discharged on a chute. The accompanying water flows down at the sides of the scraper paddles into the tank, leading to preliminary dewatering of the discharged sludge. Only the use of the scraper belt as conveyor enables the minimized height of this type of Leiblein lamella separator.

Designed for use in confined space

Anywhere low heights are required, this special line of separators can be used for process water treatment. Thanks to the scraper discharge, even relatively large and heavy particles like sand or swarf can be removed. The latter is pumped from the machining station to the scraper belt lamella separator, there the swarf and other solid particles are removed and dewatered before they are discharged. The clean process water can be reused. In applications where relatively large quantities of very fluid sludge flocs are produced, the combination of scraper and sludge pump is the right choice.

The line of machines includes another special model that offers a solution, for example, for companies that deal with sewer flushing: the scraper belt tank. This manages without lamellae, so that a suction vehicle empties its entire content into the tank, the scraper belt discharges the solids, the pre-clarified water is drained off after a delay.

Pilot plants as a basis for optimum decision-making

In many branches, the treatment of process water often starts from very different conditions. Finding the right solution to meet requirements demands a great deal of know-how and experience. As reported by Leiblein, scraper belt lamella separators are available for pilot-scale testing to determine the required size with clarifying areas of 19 – 100 m². The low-cost field tests can be supplemented with the application of other machines from Leiblein‘s extensive fleet such as pumps or the sand filter, inclined filter, and belt filter lines. In this way a complete water treatment plant can be trialled.

//www.leiblein.de" target="_blank" >www.leiblein.de:www.leiblein.de