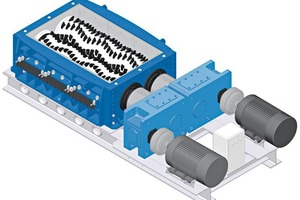

RollSizer DRS 660X3000 S – tailored to the coal industry

As one of the leading suppliers of crushing equipment for the minerals, mining and cement industry, the Industrial Solutions business area of thyssenkrupp will be presenting the RollSizer DRS 660X3000 S at bauma 2016. thyssenkrupp RollSizers are capable of crushing medium-hard rock as well as sticky and soft material. The complete series has recently been standardized and further models have been added. As a result the entire range of applications, from primary to tertiary crushing of coal, can now be handled by RollSizers from thyssenkrupp. In addition these machines are now available at significantly lower prices and with shorter delivery times.

With a roll length of 3 meters and shaft center distance of 660 mm, the RollSizer DRS 660X3000 S is the second largest member of the family of secondary and tertiary RollSizers from thyssenkrupp. The model, which will be exhibited during bauma 2016, is designed as SideSizer. Its rolls rotate outwards in opposite directions and crushing takes place between the rolls and the end walls of the housing. This is key to the crusher’s extremely high throughput rates, clearly defined final product, and very compact design.

Like all secondary and tertiary crushers from the thyssenkrupp RollSizer range, the RollSizer DRS 660X3000 S is fitted with exchangeable crusher segments made of wear-resistant steel which are durable and also quick and easy to replace. In addition, all sections of the housing that come into contact with the material during crushing are lined with wear plates. This maximizes the service life of the overall machine and minimizes maintenance requirements. The crushing combs arranged laterally on the end walls are available in various designs. Both the crushing combs and the end wall plating are horizontally adjustable so that product particle size can be precisely adjusted in line with requirements.

The DRS 660X3000 S operates with an extremely robust direct drive system consisting of two spur gears with fluid couplings. The couplings allow start-up of the Sizer even under the load of a full crushing chamber and at the same time provide overload protection. In the presence of a foreign body, the slip of the fluid couplings protects the machine against damage. The required drive torque is provided by two powerful 250 kW electric motors. To ensure maximum operating safety, all thyssenkrupp RollSizers are fitted with sensors for monitoring the main machine parameters such as drive speed, bearing temperature and lubrication.

Stand: B2.203

$(LEhttp://