Two large banana screens for the coal preparation in Vietnam

JOEST has designed and built two banana screens with special screen decks for a large coal power plant in Vietnam. The customer is using the screens for the preparation of the coal before the furnaces. These high-performance screens process coal with a maximum granulation of 20-40 mm, ensuring it is optimally prepared for the combustion process.

The customer is using the screens on two furnace feed lines. The banana screens each have a screening area of 25 m2 and a throughput of 1400 t/h. With a length of nearly 10 m and a width of almost 3 m, transporting the screens from Duelmen to Vietnam presented a considerable logistical challenge. The installation in a very narrow screening plant was a challenge JOEST had to manage. Thanks to JOEST’s long-standing experience as one of the world’s leading manufacturers of industrial screens, these difficulties were successfully overcome by experienced JOEST personnel on site.

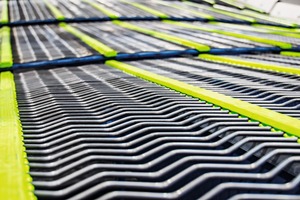

During the rainy season in Vietnam, the coal’s moisture content is higher than normal. Therefore, a combination of a special finger screen and a screen deck with a self-cleaning function was chosen for optimal screening. This combination improves the screening efficiency by allowing fast screening of the smaller material.

The banana screens are equipped with a completely dust-tight cover, dust extraction nozzles and large inspection openings. The transfer points for both fine and coarse material were also completely sealed. Once more JOEST could offer a tailored and efficient solution by many years of experience and expertise.

$(LEhttp://