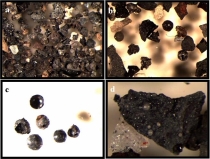

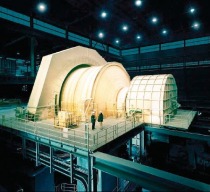

Since October 2009, the former Humboldt Wedag Coal & Minerals Technology GmbH has been part of McNally Bharat Engineering Company Ltd. (AT INTERNATIONAL reported in its 03/2010 edition, see p. 33). Despite its new name, MBE has remained true to its customers in its products. This was the background for an interview between a young face and the AT INTERNATIONAL editorial team concerning a well-known and proven product. Dipl.-Ing. Katrin Menninger (formerly Andres), Senior Project Manager for PALLA® vibrating mills, spoke to Dr. Petra Strunk. AT INTERNATIONAL: Frau Menninger, AT INTERNATIONAL readers meanwhile will recognise your photo – you appear in an MBE ad for the PALLA® vibrating mill, with the „The essentials endure“ claim. Are vibrating mills a new field for you? Menninger: I was assigned responsibility for world-wide service and marketing for PALLA® vibrating mills, as Project Manager, just on three years ago. I was already working for KHD Coal & Minerals Technology GmbH, and I stayed on at MBE Coal & Minerals Technology GmbH after the sale, with all the experience I had gathered up to that point. AT INTERNATIONAL: What applications are especially suitable for the PALLA® vibrating mill range of products (see information box)? Menninger: These mills are particularly suitable for fine and ultra-fine comminution of materials with extremely differing properties, ranging from soft to extremely hard products. But the PALLA® is also suitable for activation, densification and homogenisation processes. Vibrating mills are used, just for example, in the mineral resources and refractories industries, in the chemicals industry, and for grinding in the ceramics, dyestuff and glass industries. The needs of the various branches necessitate a versatile and variable vibrating mill concept; variants include dry and wet grinding, continuous and discontinuous grinding processes, indirect...

more