Mobile on the rise

Materials handling equipment in the rock and aggregates industry

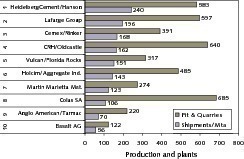

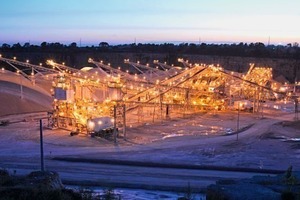

Summary: Quarries are very energy and capital-intensive. Sand and gravel works are somewhat cheaper to run. Given the low tonnage profits, it is therefore all the more important for producers of broken natural stone, gravel and sand that cost-effective production equipment is employed. The market for these products is highly fragmented. The TOP 10 western companies only have a share of 6.3 % in the annual worldwide production quantity of 22 500 million tonnes. This report presents an overview of the industry with market data, the most important companies on the sector and the employed equipment. Particular emphasis will be placed on the materials handling equipment.

1 Introduction

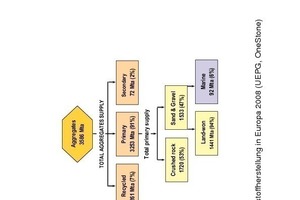

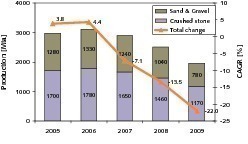

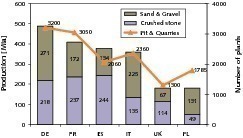

Most of the mineral raw materials extracted worldwide originate from quarries, sand pits and gravel pits. In 2009, approximately 22 500 million tonnes (Mta) of product were extracted worldwide, which split up into approx. 60 % sand and gravel and 40 % broken stone (natural stone). The bulk of these products were used for road, rail bed and waterway construction or as concrete and asphalt aggregates. For one kilometre of motorway about 10 000 t of these materials are needed. The complex range of demands placed on aggregates, which include construction sand and gravel, largely...