Development of the conveyor industry in South Africa’s raw materials market

W ith the “one-stop shop” model, REMA TIP TOP supplies industrial products and services in South Africa. In recent years, many German industrial enterprises have also recognized the strategic importance of stable “global sourcing” and established production sites directly at key raw material sources. But the more international the value-added chains are, the more complex are the processes and risks in daily business.

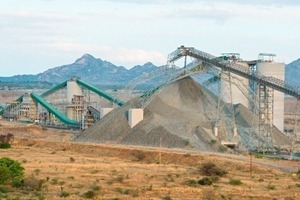

There is a demand for “one-stop shop” models in which a supplier supplies several products and services from one or similar business segments in high quality directly at the production location. The traditional German company REMA TIP TOP has shown how this works. The expert on industrial wear protection has been present in South Africa for years, supplying products and services to the mining industry, a key raw materials market (Fig. 1). With the alliance with Dunlop South Africa, the rubber manufacturer based there, REMA TIP TOP can now supply even more services from one source.

Belt conveyors are essential equipment in the manufacturing and extraction industry (Fig. 2). In the truest sense of the word, they are a particularly sensitive link in the value-added chain: if a belt conveyor fails on account of a defect or for maintenance, the entire operation grinds to a standstill. To prevent these down times, a number of specialists have become established in the conveyor sector: if you operate a conveyor anywhere in the world, then you can usually rely on the support of different manufacturers and service companies. For 40 years REMA TIP TOP South Africa has supplied belt conveyors along with the appropriate maintenance and service (Fig. 3). With the alliance with the rubber manufacturer Dunlop South Africa, the company is extending its range in line with the “one-stop shop” model. This enables REMA TIP TOP to adapt its services quickly and precisely to individual customer requirements, for example when it is a matter of the material properties of belt conveyors. Especially companies that operate globally will profit from this as with the service network of REMA TIP TOP, Dunlop South Africa is present almost all over the world and able to professionally install the belt conveyors.

Already with regard to the material properties of the conveyor belts, the pooling of the expertise of the two companies – rubber manufacture and belt conveyor service – benefits product quality. The organizational merger of the REMA TIP TOP plants with the Dunlop production plants in Howick and Benoni ensures more effective utilization of production capacities. The entire production steps such as the mixing shop, calendering, presses and shaped parts depend on the same supply of compound from Dunlop South Africa and are integrated in the new infrastructure. Four mixer lines enable mixing capacities up to 22 000 t/a. With the newly extended plants for belt conveyor production, REMA TIP TOP can supply customers with belts and sheets in line with their requirements without waiting times, even in the case of large order volumes (Fig. 4). “Besides conveyor belts, our buyers can now obtain pulley lagging, guide rubbers, as well as wear and surface protection services from us. We meet all customer needs concerning traditional and individual rubber conveyor articles, but we also produce textile and steel cord belts ourselves,” explains Thorsten Wach, Managing Director at REMA TIP TOP South Africa.

The alliance with Dunlop South Africa brings a wide range of synergistic effects such as an extended range of products, shorter channels, higher capacities and not least end-to-end quality assurance. With responsibility both for the production and the maintenance, it is possible to continuously check the condition of the materials. This means synergistic effects for new areas of business and a continuous build-up of know-how. “With the further training and qualification of our employees in the new business segments, we are raising the level of engineering in the company. For example, our customer service and sales representatives receive expert backup and support with regard to technical questions concerning the belt, its installation and maintenance,” explains Wach.

Over the last ten years, REMA TIP TOP has doubled its global manufacturing capacities. A development with which the company would like follow up with the extension of the site in South Africa. According to Thorsten Wach, this is particularly suitable for the investment on account of the variety of raw materials (Fig. 5): “The speed with which the promising market is growing in Africa with its wealth of raw materials is also a political issue. In this connection, especially market development in the threshold markets of China and India plays a big role. Business here is no different than in the rest of the world: a company must be competitive, clearly present its competences and optimally fit into the buyer’s value creation chain.”