Dewatering of special (metal) sludges

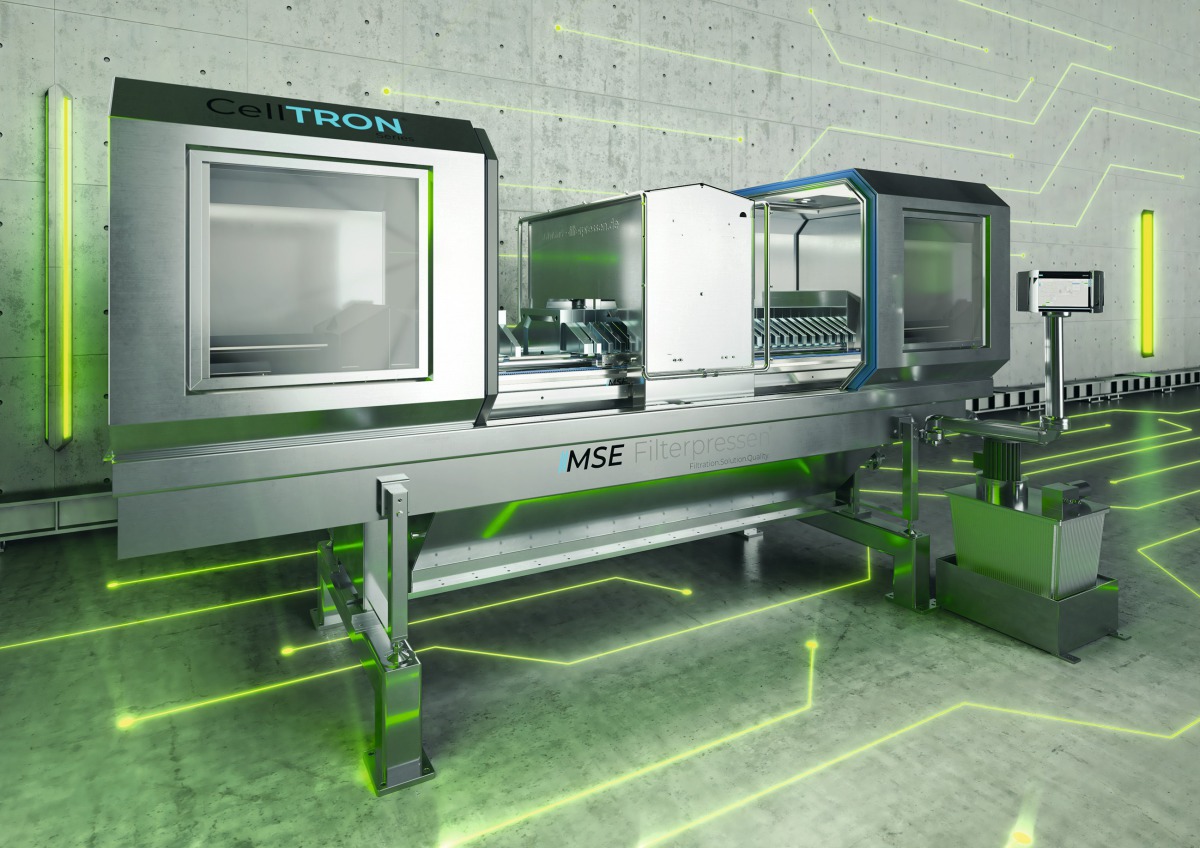

CellTRON® filter press from MSE

CellTRON® filter press from MSE

© MSE

The Celltron filter press from MSE aims to help fulfil the ever-increasing demand for batteries of highest storage density and reliability. MSE say that the design has completely revised the traditional filter press system. In close cooperation with industry-specific customers, a high-performance filter press has been developed that is second to none.

CellTRON® for maximum filtration requirements

The new product series features an industry-leading and innovative filter press emptying system with lifetime error message, an automated filter cloth washing system with implemented CIP-function, and an automatically opening machine housing with integrated swiveling funnel for filter cake discharge. In contrast to conventional filter presses, the manufacturers claim that new development guarantees a complete, almost gas-tight encapsulation of the filter press while protecting the operating personnel and ensuring product quality.

CellTRON® Xtreme filter press

CellTRON® Xtreme filter press

© MSE

According to MSE, this filter press technology meets the specific requirements for the dewatering of special (metal) sludges in harsh environments, e.g. filtration of sludges containing lithium, nickel and cobalt. CellTRON® filter presses are thus suitable for the most demanding applications that require highest safety and efficiency standards and maximum operational reliability. These also include volatile, dust explosive products as well as substances with toxic and radioactive properties but also PharmaFood products and hot suspensions (≥ 130 °C).

The CellTRON® press filters are available in sizes from 470 x 470 mm for pilot plants up to 2000 x 2000 mm for highest capacities with filter areas from 1m2 to 1300 m2. Each plant is supplied with piping, valves, instruments, pumps and tanks.

Recently, MSE has secured another major order for battery production. Here, MSE is supporting the delivery of Europe’s largest “green battery” production plant with 5 of its newly developed CellTRON®Xtreme filter presses.