Fertilizer production with the HAVER pelletizing disc SCARABAEUS

In view of the increasing food requirements of the world’s population and the continuing eluviation of the soil due to intensive agriculture as well as the loss of arable land following sealing of surfaces in urban environments, the exploitation of raw materials and the contamination with pollutants, fertilizers are becoming more and more important in the production of foodstuff.

Plant growth and harvest quality generally depend on how much of the required nutrients there is in the soil. The nutrient of which there is least defines the success of the cultivation. It follows that fertilizers are needed to make up for any deficits. Today, great demands are made on the fertilizers used to increase the yield of crops, for example regarding the mineral combination which supplies the plants with nutrients, or regarding the structure and shape of the fertilizer pellets to improve the flight behaviour when the pellets are spread.

The company Australian Mineral Fertilisers produces fertilizers under the brand name GrowSafe® in Tenterden/West Australia (Fig. 1). The biological mineral fertilizer is a material mix. Every pellet contains all combinations of minerals. The pellets are suitable for spreading with standardized sowing and fertilizer distributors. They are sold in Big Bags, 25 kg bags, or as bulk material.

In recent years, the company was faced with the question whether a 10-year old pelletizing drum could be safely replaced by a pelletizing disc to increase production capacity and product quality. Owing to the complexity of the processes, the production of mineral fertilizers by means of the pelletizing drum proved to be increasingly complicated and highly inefficient due to the high volume of undersized and oversized pellets beyond the specified product range. The requirements made on a pelletizing disc were very high: In addition to a significant capacity increase from 7 to 20 t/h, it was to improve product homogeneity as well as product quality.

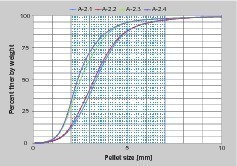

In late 2011, Australian Mineral Fertilisers directly contacted HAVER NIAGARA in Münster. Both sides quickly agreed that test runs were required to provide a basis for further discussion and for dimensioning the system components. In cooperation with HAVER ENGINEERING, a test concept was generated to investigate the suitability for pelletizing, which drew the interest of the project owners at AMF’s. Already in spring of 2012, an AMF associate together with the Plant Manager came to the site of HAVER NIAGARA to gain a personal impression of the manufacturing capacities. They also visited the R&D Center of HAVER ENGINEERING in Freiberg, to learn more about the results of the research. A presentation of detailed results and the demonstration of agglomeration tests with AMF fertilizers convinced the customers of the capabilities of HAVER SCARABAEUS. With up to 80 M.-%, the share of usable fertilizer pellets, produced in the tests under laboratory conditions, exceeded the expectations (Fig. 2).

Based on the results of the test runs, the decision was made to replace the pelletizing drum by a pelletizing disc of the HAVER SCARABAEUS® series. The features that made AMF decide on the HAVER SCARABAEUS SC4200 (Fig. 3) were the robust design, the energy-efficient and low-maintenance drive unit with two asynchronous motors, which allow for start-up even under full load and ensure continued operation if one of the motors fails, as well as the system’s high flexibility, such as the possibility to adjust inclination and speed during ongoing operation.

Around the time this decision was made, HAVER AUSTRALIA was established in Perth/West Australia. This means that the parameters for designing and dimensioning the system could be coordinated quickly, reliably and at low costs between the customers and HAVER NIAGARA. In addition to the pelletizing disc HAVER SCARABAEUS SC4200 complete with its control system, a HAVER NIAGARA T-Class 1500 x 5000 for product grading and a Computer Particle Analyzer CPA 2.1 of the wire weaving company for continuous determination of product quality was sold. Other machines from the extensive product portfolio of HAVER NIAGARA are already operating successfully in the chemical fertilizer industry (MAP, DAP, NPK).

With 61 M.-%, the share of usable pellets in the product was above the level of the previously used drum already during the commissioning phase of the pelletizing disc in autumn of 2013. Today, after completed commissioning and some months’ worth of experience, the rate of yield for AMF is up to 80 M.-%. Even the solidity and roundness of the pellets improved significantly. The Plant Manager confirmed that his customers had registered this distinct improvement in quality and said that they were very satisfied. After the completion of commissioning, HAVER Australia took over customer service. They will carry out the regular maintenance of the machines and support the customer in future process optimization.

//www.haverniagara.com" target="_blank" >www.haverniagara.com:www.haverniagara.com