Remove dust at the right place

The top-mounted filter unit BAF from the DFT GmbH Deichmann Filter Technik is a highly effective filter with minimum footprint. The structure of the BAF with its highly efficient Deicolon filter elements is simple and powerful. The Deicolon filter elements have frequently proven their worth in the market. They consist of spiral filter tubes arranged in a row on a carrier and provide excellent filtration properties. The particular shape results in good backflushing characteristics and low flow resistances. Compared to folded surface filters, significantly higher filter surface loads can be realized. For this reason, the top-mounted filter unit shows a significantly lower pressure difference and consumes less energy than filters of the other design, but at comparable filter surface load.

Due to the new, innovative and patented DELA compressed-air cleaning and generation integrated in the filter, separate compressed-air supply is no longer necessary. By using compressed air with a system pressure of approx. 3.5 bar instead of the usual 6 to 8 bar, the electrical energy required for the generation of the same volume of compressed air will be reduced to about 60 %.

The compressed air can be generated decentrally by oil-free compressors. In most cases, a simple cooler is sufficient and a dryer is no longer needed. The losses of compressed-air due to slow, uncontrolled closing of the membrane valve will be reduced considerably (approx. 20 – 30 %). The overall savings amount to about 40 – 50 %.

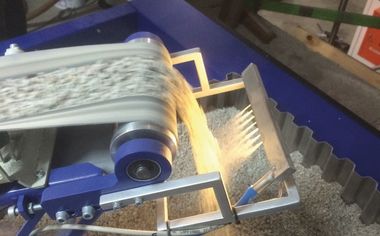

The BAF, as the decentral filter unit, which, depending on the belt width, cleans a crude gas volume of 1500 m³/h to 5000 m³/h, is mounted directly onto the conveyor belt and filters the often harmful dust directly where it arises. The strain for employees, environment and machinery will thus be reduced considerably.

Thanks to the BAF, the residual dust content in the clean gas amounts to less than 1 mg/Nm³, leaving the gas almost unpolluted. Also in terms of dust discharge, the operating mode of the BAF is cost-effective and can be realized without any additional technical equipment. Due to the integrated compressed-air supply, the dust adhering to the filter elements will be automatically returned onto the conveyor belt by a compressed air pulse and will then be removed along with the material to be transported. Thus, the use of a cellular wheel sluice and a dust collector is no longer necessary. The standard version of these filters can be used up to a temperature of 80 °C, special designs for temperatures of up to 200 °C are possible. Due to the low differential pressure, the long service-life of the filter elements, the compact design, the low energy consumption and the fully-automatic and autonomous dedusting, the top-mounted filter unit from DFT GmbH Deichmann Filter Technik represents an extremely attractive and cost-effective solution for dust removal with versatile fields of application.

The DFT GmbH Deichmann Filter Technik is strongly committed to channel dust formation in a sustainable way. Since its foundation in the year 1947, when Hermann Deichmann opened up a technical office in the Hessian town of Bebra, the company developed into a technology leader in industrial dedusting. During the company’s history of more than six decades, numerous path-breaking innovations were brought to market maturity. The modern dedusting systems of the DFT GmbH Deichmann Filter Technik provide a filter performance ranging from 1000 m³/h to more than 500 000 m³/h. Since 2015, the DFT GmbH has been part of the international group CFH GmbH. The cooperation of the companies provided the basis for the extension of the respective product program. The focus of the entire group is on the topics of “Clean Air” and “Occupational Safety”

//www.deichmann-filter.de" target="_blank" >www.deichmann-filter.de:www.deichmann-filter.de