The right belt for every task

2015, GKD – GEBR. KUFFERATH AG‘s WEAVE IN MOTION division took its integrated capabilities in the field of filter belts as the central focus of its presence at the fair. The dewatering, filtration and drying of the various substances plays a central role in their conversion to concentrates and/or dry products. WEAVE IN MOTION, with its large bandwidth of filtration products, provides versatile solutions for such special applications (Fig. 1).

Dewatering

The company‘s process-belt solutions, tried and proven in the most diverse applications, make an important contribution to process-efficiency in the dewatering of municipal and industrial sludges. Belt types with widths of up to 8 m designed specifically for each application simultaneously assure high sludge retention rates and effective dewatering under virtually all chemical and mechanical conditions.

Filtration

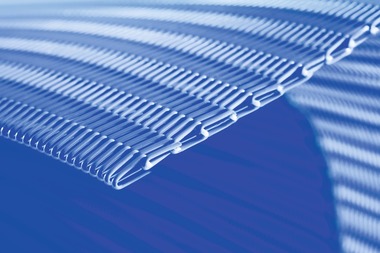

Whether in FGD-gypsum dewatering with a 50 μm aperture (Fig. 2), for filtration of cooling lubricants with apertures in the 80 to 120 μm range, in production of phosphoric acid, with 150 to 250 μm aperture types, or in the filtration of salts or minerals, using apertures of up to 500 μm: the special mesh design of VACUBELT® filter belts – assuring dependable lateral stability even in large belt widths – convinces users in the most diverse range of specialised applications with its optimum air-permeability and constantly high filter performance, low proneness to clogging and excellent ease of cleaning (Fig. 3).

Precision

As a technological leader, GKD sets standards in advisory services, design, development and production of filter and dryer belts for the process industry: dependable repeatable pore accuracy contributes to achieving the necessary production reliability, as do high flexibility, quality and tracking accuracy. Individual joints, which minimise particle loss thanks to their extremely small apertures, additionally underline the efficiency of these belts.