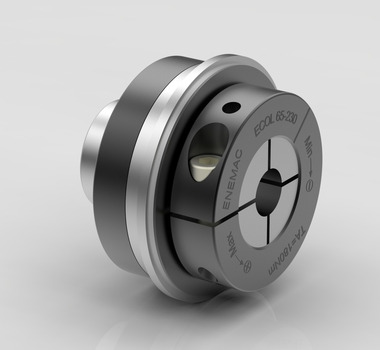

Three new N-Eupex couplings and optimized flexible elements

Flender is expanding the portfolio of its flexible coupling series N-Eupex by introducing three new types. The new products allow users additional flexibility in their systems without losing the compact design and high load capacity of a pin coupling.

The three new couplings N-Eupex ERN with torque limiter (right), N-Eupex B with clamping element (left) and N-Eupex DKS with shortest double-cardanic design (center)

The three new couplings N-Eupex ERN with torque limiter (right), N-Eupex B with clamping element (left) and N-Eupex DKS with shortest double-cardanic design (center)

© Flender

The new N-Eupex ERN is equipped with a torque limiter, which provides even more security in the drivetrain in many applications. The coupling variant allows users to specify a maximum torque so that critical torques for the motor and output machine are not transmitted. Machines and systems are protected from overload and damage, thus significantly increasing system availability. With the N-Eupex B plus clamping element, Flender introduces a second new coupling that ensures frictionally engaged clamping connections. In this case, the plain, cylindrical machine shaft end is connected to the coupling hub via a clamping connection without a feather key and service ability is increased. For example, assembly or replacement of worn elastomers can be carried out much more easily. With the N-Eupex DKS, a new double-cardanic coupling is introduced as a “short version” into Flender’s modular system. While the DK type, which was launched in 2020, addresses the pump market with standard expansion pieces for normed shaft distances, the DKS is the shortest possible double-cardanic solution for the market. The shortened overall length enables cost-optimized use with a small shaft distance dimension without losing the advantages of a double-cardanic coupling connection.

New elastomers for the pin couplings round off the modular extensions. In addition to the previously used rubber elements made of NBR, Flender now also offers elastomers made of thermoplastic polyurethane (TPU). Following the torque increase for all N-Eupex couplings with NBR packings in 2020, the use of TPU packings allows the power density to be increased by another 20 % on average. For sizes 300 and above, the familiar NBR elastomer is combined with fabric inserts and the torque capacity is again raised.