Sustainable and efficient production of iron ore pellets with HAVER & BOECKER NIAGARA

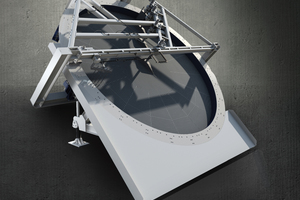

HAVER & BOECKER NIAGARA is launching a new landing page – http://haverniagara.de/pelletizing/ – presenting an innovative pelletizing technology: The SCARABAEUS® 7500 pelletizing disc, which aims to apply the own understanding of the company for sustainable and efficient iron ore production. The new page and the new technology as well are a part of the mission Planet Blue making an impact of the more careful use of resources and materials and contributing to the environmental protection.

The new landing page shares important information about iron ore & pelletizing technology. Scrolling through the different sections, the users quickly find out detailed overview of improvement of resource efficiency using the innovative HAVER & BOECKER pelletizing disc SCARABAEUS® 7500 and come across information about pelletizing service of HAVER Engineering. They discover how pelletizing process makes the distribution of very tight particle size possible and learn why pelletizing technology is so important for the enrichment of iron ore.

“The SCARABAEUS® 7500 with its unique SCARABAEUS process control is a strong tool for the operators to achieve specification of tomorrow by use of long term practical experience. The experience of more than 50 years of common pelletizing of iron ores is the basis for Industry 4.0 in harsh industrial environments,“ said Dr. Jan Lampke, Head of sales at HAVER ENGINEERING GmbH.

Benefit 1: Improved product quality

The Scarabaeus process creates higher quality pellets, which can be sold at better prices due to significantly tighter particle size distribution spread and a higher iron ore content.

Benefit 2: Increased product output

The Scarabaeus process generates higher tonnages by minimizing the material return rates and avoids double processing of over or undersized pellets due to automatic machine parameter adjustments, which can also adapt to varying material property fluctuations in the feed material.

Benefit 3: Reduced CO2 emissions

The Scarabaeus process creates pellets so high in quality that they can be utilized for the direct reduction process. This in return can create enormous CO2 emission savings, thus minimizing the mine’s impact on the environment.

The landing page presents SCARABAEUS® 7500 pelletizing discs used for agglomerating iron ore concentrates into pellets with very tight particle size distribution (target size of 10 to 14 mm) and supporting DRI-Process (processing method for sustainable and efficient production of iron ore): “It is the direct iron ore reduction process, enabled by those uniform size pellets, which finally leads to the tremendous reduction in greenhouse gases. This innovative pellet based solution avoids the traditional blast furnace route and, hence, the energy intensive smelting of the ore and ensures the production of 97 % pure iron at the end. This is such a great contribution to protect our climate through technology innovation”, said Prof. Holger Lieberwirth, Director of Institute of Mineral Processing Machines at Technical University Bergakademie Freiberg.

The optimum operating parameters of the disc can be set by automatic adjustment of the inclination, the rotational speed, the mass flow rate, and now also the rim height thanks to the innovative automatic pelletizing disc control system. The quality of the product is ensured thought the integrated camera system: because you can only manage what you can measure. In order to determine which process is the best for the customers iron ore and pellets requirements and to provide the possibility of achieving the desired parameters HAVER & BOECKER NIAGARA conducts iron ore tests in their Associated-Institute of TU Bergakademie Freiberg – HAVER ENGINEERING GmbH. All technical details, product advantages and also information about the mission of Planet Blue are briefly listed on the new page.

The landing page contains also an integrated social media buttons for Blog, Facebook, Instagram and Linkedin to foster improved communication with the customers. Do not forget: “Power is gained by sharing knowledge, not hoarding it” (Maria Khan)! Let this knowledge reach as many people as possible! Share the innovation of HAVER & BOECKER NIAGARA: http://haverniagara.de/pelletizing/ & make your small but sure contribution to the mission Planet Blue: “Together to more careful use of resources and materials”.

P.S.: If you would like to send your feedback about your experience with the page, please send an email: pelletizing@haverniagara.com