Binder+Co AG

1 Sensor-based sorting with CLARITY and MINEXX

1 Sensor-based sorting with CLARITY and MINEXX

© Binder+Co

MINEXX and CLARITY provide an AHA in the sorting of raw materials and in construction waste recycling

Sensor-based sorting has been working with artificial intelligence (AI) for a long time. AI enables the interaction of multiple sensors to process valuable raw materials, such as in the separation of talc and magnesite. These two minerals can only be separated by their material differences, i.e. differences in the non-visual range. If additional sorting by color is required (for example, light and dark talc), the sensor system is equipped with color cameras in addition to cameras for material recognition.

The requirements in the processing of minerals, building materials, but also in construction waste recycling are becoming more and more demanding. Higher material qualities with less material loss is often the task here.

Color and material sensors are now coupled to information about the surface properties of the material to be sorted. This enables an even wider range of sorting solutions. For example, in construction waste recycling and excavated soil: a high asphalt content significantly reduces the quality of recycled crushed stone. If separation by color (black) were to be relied upon here, a considerable loss of material would have to be accepted, as a great amount of good product would also be sorted out due to contamination in the form of valuable, asphalt-colored natural stones. Here, Binder+Co relies on object recognition through “deep learning”. The result: the construction waste is reliably separated from asphalt with marginal material loss and can be reused as recycled crushed stone.

Binder+Co’s goal is to make sorting economical above all else. CLARITY and MINEXX not only create high-quality products for processors, but also keep the operating costs of the sorting system low by long-life sensors.

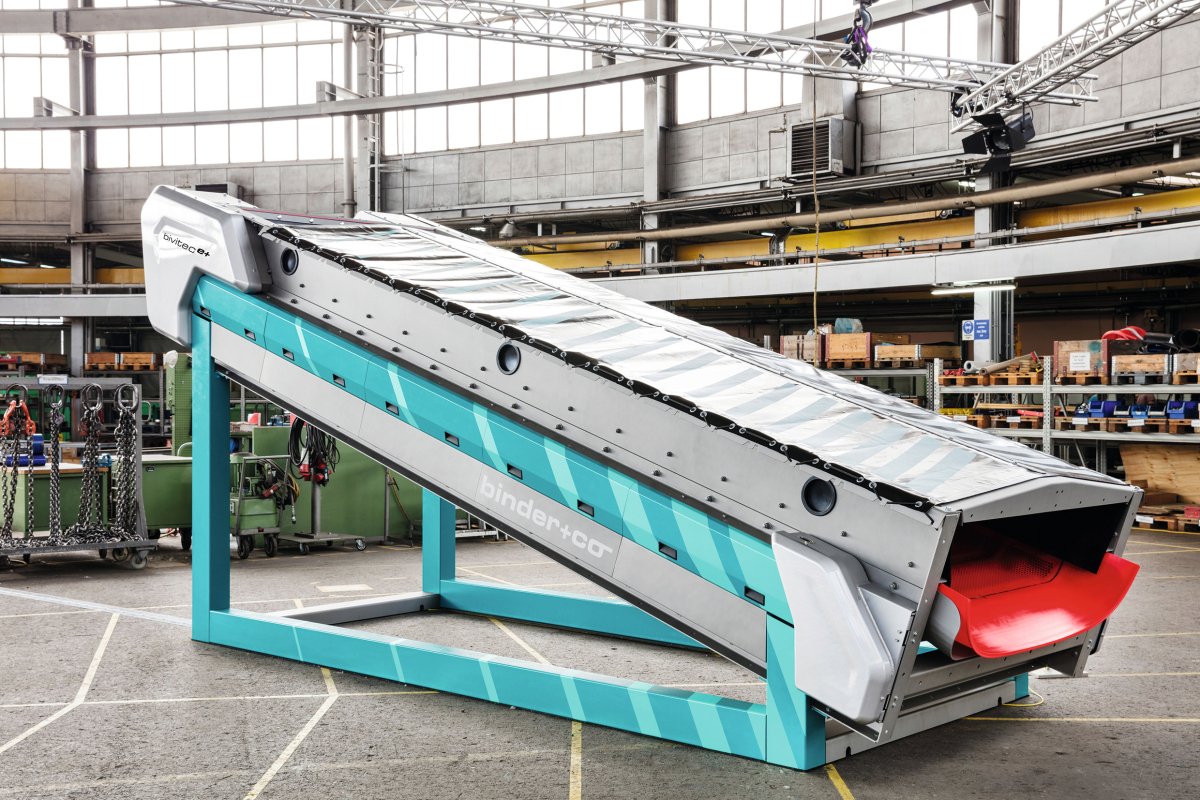

2 The BIVITEC e+ is characterised by a lightweight design and thus significantly lower drive power

2 The BIVITEC e+ is characterised by a lightweight design and thus significantly lower drive power

© Binder+Co

BIVITEC e+ large in effect, small in consumption

The BIVITEC flip-flow screen is a well-known and appreciated solution for screening problematic materials, such as those frequently encountered in the processing of crushed stone, gravel and sand. Binder+Co has now added an energy-saving variant to its flip-flow screens.

This latest development is called BIVITEC e+ and is unbeatable in terms of investment and operating costs. The BIVITEC e+ combines two classics from the Binder+Co screening machine program: the low dynamic loads due to mass balancing of the resonance screening machine and the flip-flow system of the BIVITEC. This means: a lightweight design and thus significantly lower drive power.

Thus, the BIVITEC e+ can save up to 40 % in weight and up to 65 % in energy. The low dynamic loads of the latest Binder+Co flip-flow system allow the dimensioning of a lighter substructure and thus a significant reduction in investment costs. This is also interesting for retrofits or machine replacements in existing plants, if the existing infrastructure does not need to be expanded or reinforced.

The BIVITEC e+ can be designed as a single-deck or multi-deck version and can be stacked as often as required. Another advantage is the adjustability of the vibration characteristics. Each screen deck can be individually adjusted and ensures that material difficult to screen is classified with high separation accuracy.

The applications of the BIVITEC e+ range from construction raw materials and industrial minerals to the most diverse tasks in recycling.

Booth B2.213