Conveyor wear liner improve safety and equipment life

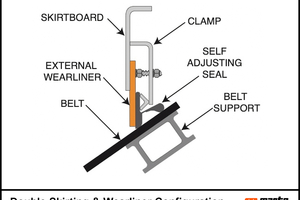

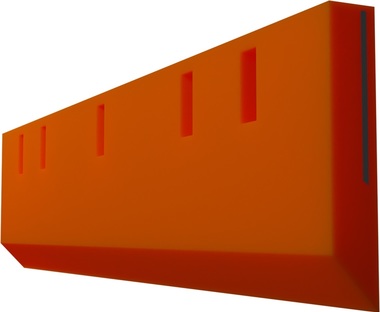

When quarry operators load the conveyor with heavy raw material, the wear liner on a belt conveyor transfer point protects the loading zone enclosure from severe abrasion and is essentially considered a sacrificial layer. Removal and replacement of this layer are challenging tasks requiring multiple workers and several days of scheduled downtime. Conventional wear liners have traditionally been installed inside the chute, but modern designs are positioned on the outside, enhancing skirtboard sealing and preventing spillage.

The goal of the external design is to significantly reduce installation and service time while minimizing risk and enhancing safety. The result is an optimized performance with fewer labor hours, no...