Laboratory WHIMS for Wardell Armstrong

1 Laboratory-scale WHIMS

1 Laboratory-scale WHIMS

© Bunting

For many years, Bunting and Wardell Armstrong have worked together on mining, mineral processing and environmental projects requiring material separation tests. The purchase of the laboratory WHIMS provides Wardell Armstrong with greater testing and research capabilities on-site at Truro. Controlled material tests on laboratory-scale high-intensity magnetic separators provide vital data on the mineralogy of an ore or deposit. The electromagnetic laboratory-scale Wet High Intensity Magnetic Separator (WHIMS) removes fine magnetics and para-magnetics from mineral slurries. Handling minerals in a slurry or suspension is preferable for many processors, especially when beneficiation involves wet processing. Additionally, a wet process often produces a better separation for very fine materials.

The laboratory-scale Wet High Intensity Magnetic Separator (WHIMS) features two electromagnetic copper coils mounted either side of a canister housing a matrix, which captures magnetically-susceptible particles. The electromagnetic coils project a manually controlled magnetic field of between 0 to 20 000 Gauss (0 to 2 Tesla) into the open gap of the canister housing the matrix. The level of magnetic field strength in the open gap is set in accordance with the separation objective and magnetic susceptibility of the minerals being processed. The magnetic field is intensified on the points of the matrix and there are various designs of matrix to suit different minerals applications and particle size ranges (down to < 2 µm).

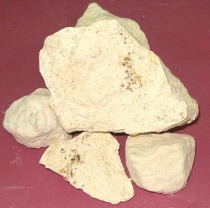

2 Magnetic minerals separated on a laboratory-scale WHIMS

2 Magnetic minerals separated on a laboratory-scale WHIMS

© Bunting

In operation, an initial evaluation of the test material determines the type of matrix and also the level of magnetic field required to meet the customers objectives. The magnetic field of the laboratory WHIMS is calibrated using the calibration graph (provided with each laboratory WHIMS). The graph shows the relative magnetic field (in Gauss) at different current levels (in Amps) with and without the matrix. The requisite level of Amps to project the required magnetic field is set on the control panel. As the magnetic field rises, the increased magnetic field strength and gradient enables the capture of weaker and para magnetic minerals.

Once the matrix and magnetic field test parameters are set, the laboratory WHIMS is activated with material gravity fed in a 15 to 20 % w/w suspension through the central matrix. Any residual material in the feed container is washed out into the matrix using a known volume of wash water. The non-magnetic minerals and the water flow through the matrix and are collected in a receptacle underneath. Magnetic particles are held in the matrix by the magnetic field. To remove a small proportion of non-magnetics potentially entrapped in the matrix, water is flushed through with the magnetic field still on. The non-magnetics receptacle is then replaced for collection of the magnetics fraction. The magnetic field is turned off, which releases the magnetically trapped particles. The matrix is once again flushed through several times with water to ensure the matrix is empty. Commonly, both samples are then dried before being analysed.

“The need to process increasingly difficult deposits and recycle materials previously classed as ‘waste’ is driving a demand for high-intensity magnetic separation,” explained Neil Rowson, Bunting’s Laboratory Manager. “Bunting already conducts extensive test work for the consultancy at our Customer Experience Centre in Redditch, but with an increasing number of projects the consultant wanted to expand their own test capabilities.”