Precise measurement of bulk material at any time with LiDAR

Volume measurement example

Volume measurement example

© Blickfeld

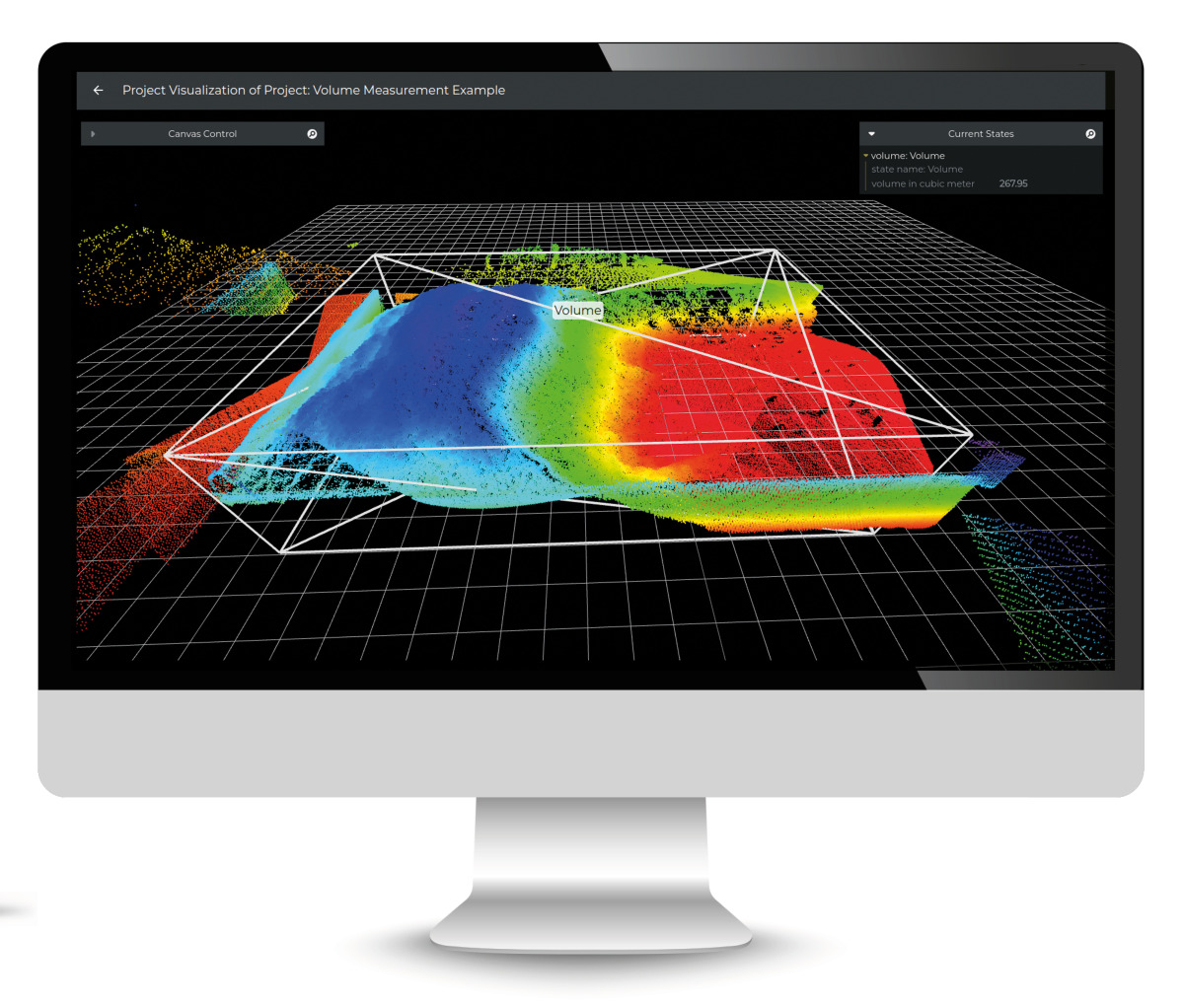

3D LiDAR technology now enables companies to cost-effectively measure bulk material inventory to the centimeter at any moment in time, providing them with real-time information about their supplies. This works by LiDAR sensors emitting thousands of laser pulses per second, which are later reflected by the materials. The available volumes of material can be calculated accurately based on the time it takes for each individual laser beam to arrive back at the sensor.

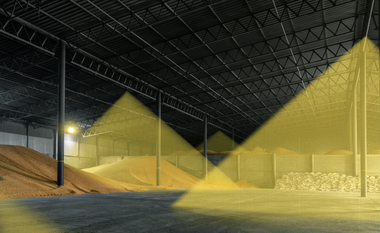

For example, Sachtleben Technology uses Blickfeld’s Cube 1 model LiDAR sensors to measure bulk material inventories. For this purpose, the LiDAR sensors are connected to adapter plates with network and power connections on the hall ceiling to which it is attached. The 3D data generated by the LiDAR sensors provide information on the height, width, and depth of the bulk piles with centimeter accuracy. The data from several sensors is fused so that the entire stockpile is recorded in a single operation. Thanks to Blickfeld’s sensors with a large field of view, only a few devices are required to measure large areas.

An example of a cross-plant application is provided by Blickfeld customer Hudbay Minerals, a Canadian mining company primarily producing copper concentrate (containing copper, gold, and silver), zinc metal, and silver/gold doré. With the help of LiDAR sensors, the company, which operates in several countries, is able to learn exactly how much material is available at the various storage sites at any given time and can coordinate processes across sites in a highly automated manner.

Hall 3, stand 677