100th Metso Outotec Anode Casting Shop

07.07.2022Metso Outotec will deliver its 100th Anode Casting Shop to PT Smelting’s (PTS) copper smelter in Gresik, East Java, in Indonesia. Metso Outotec has been a frontrunner in the development of anode casting technology for several decades. Today, most of the world’s copper anodes are produced with Metso Outotec’s proprietary anode casting technology.

“The Gresik project marks a true milestone for us. The system to be delivered to PTS is one of the world’s largest Twin Wheel Anode Casting Shops with a guaranteed capacity of 120 t/h,” explains Sami Maaniittu, Director, Anode Casting, at Metso Outotec.

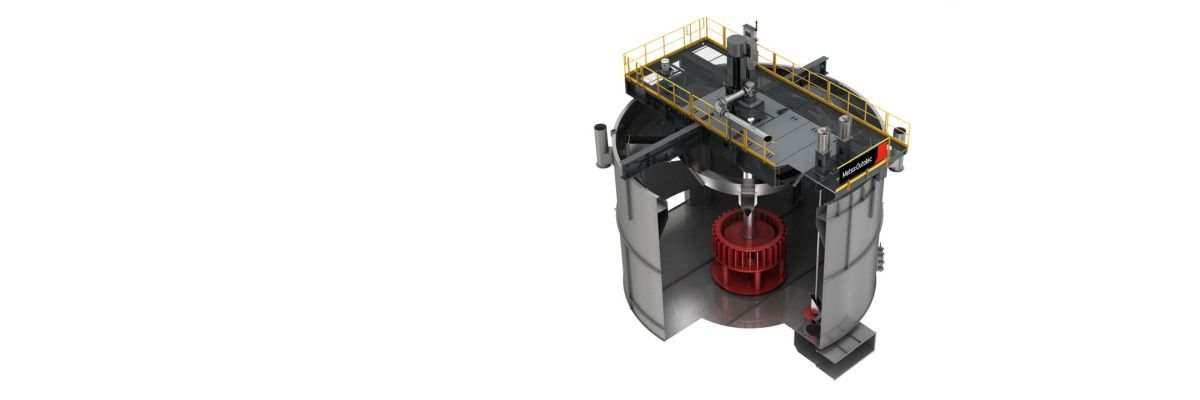

Metso Outotec Twin Wheel Anode Casting Shop

Metso Outotec Twin Wheel Anode Casting Shop

© Metso Outotec

Over 50 years of innovative anode casting technology development

“We started the development and testing of automatic anode casting already in 1969 in Harjavalta, Finland. Before that, castings were made manually with controlled ladle tilting. The first anode weighing and casting machine was delivered to the USA in 1972, and a year later, the first complete anode casting shop was installed at the Harjavalta Smelter in Finland,” says Maaniittu.

Metso Outotec’s Twin Wheel Casting concept, paving the way for today’s industry standard, was developed in the 1990’s. The optimized equipment design significantly improves casting capacity and provides more efficient use of floor space. The wheels are supported on large center bearings and driven by double drive systems developed to eliminate the backlash effect in the wheel movement and to ensure even quality. The first Twin Wheel Anode Casting Shop systems were delivered in 1997. Since then, the Twin Wheel has become the first choice of high-capacity anode casting shops.

Top-of-the-line electric casting system ensures premium anode quality

Today, most of the anode casting shops supplied by Metso Outotec are fully electric without any hydraulic systems. Their high level of automation ensures premium anode quality with excellent weight accuracy and low reject rate combined with high capacity and availability. Metso Outotec Anode Casting Shops are safe and easy to operate and feature low energy consumption.

In addition to full anode casting systems, Metso Outotec offers a variety of modular updates for the existing installations, including automation and services.