06.12.2012 / Small but Lödige

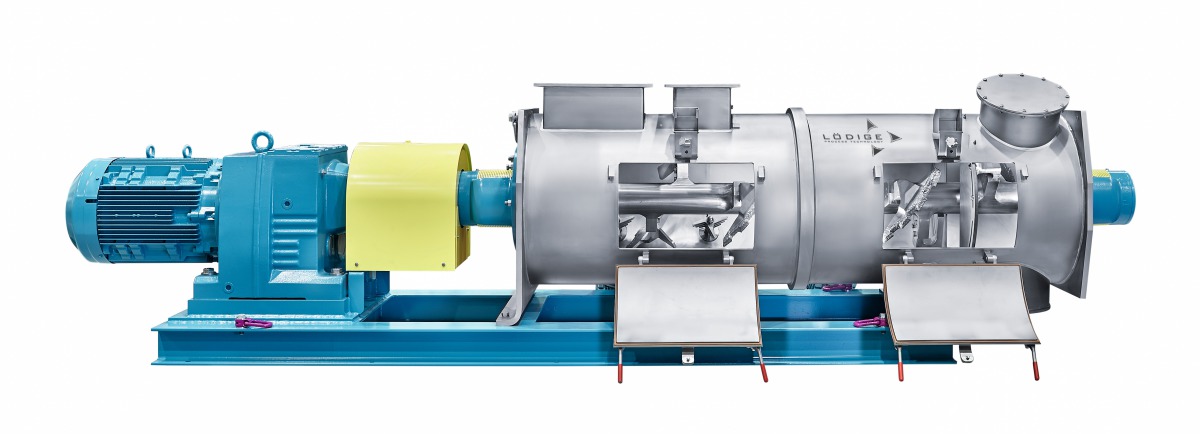

With the new Ploughshare® Type N 5 laboratory mixer Lödige has expanded its range of laboratory equipment for small mixing quantities: the drum has a volume of 5 litres. This model is thus ideally suited to the development of products and processes as well as for small-scale production. Suitable applications are to be found particularly in chemical and environmental engineering. For example, minerals, basic and building materials as well as moulding compounds can be processed with the new laboratory mixer.

The mixer was conceived as a compact table model. It is completely assembled, tested and thus ready for use. Furthermore, this new generation of machines is characterised by consistently functional and ergonomic design. The control unit is an integral part of the housing. Due to the deliberate use of proven standard components, the N 5 offers the highest quality standards at an attractive price. In operation the infinitely adjustable speed of the mixer shaft will prove to be a major advantage. In addition, the new laboratory mixer with standard equipment has a detachable front plate. The entire vessel with front plate can be rotated for filling and emptying the mixing vessel through the same neck. This also facilitates cleaning.

As an option the Type N 5 laboratory mixer can be equipped with a wide range of application-specific accessories. The accessories include, for example, a feeding hopper or spray lid for systematic addition of liquid products.

www.loedige.de