Measurement of light and heavy elements in flotation circuits

29.11.2022Metso Outotec is introducing the Courier® 8X SL analyzer with enhanced technology for maximizing plant efficiency by enabling the measurement of light elements while improving recovery and reducing impurity content in flotation circuits. “Courier® 8X SL uses Laser Induced Breakdown Spectroscopy (LIBS) technology to measure both light and heavy elements to monitor and control the operations of minerals processing plants; this enables optimization of concentrate impurity content while maintaining the best possible recovery. The analyzer can also be used to optimize lithium recovery in spodumene flotation,” says Veli-Matti Järvinen, Automation Vice President, Separation at Metso Outotec.

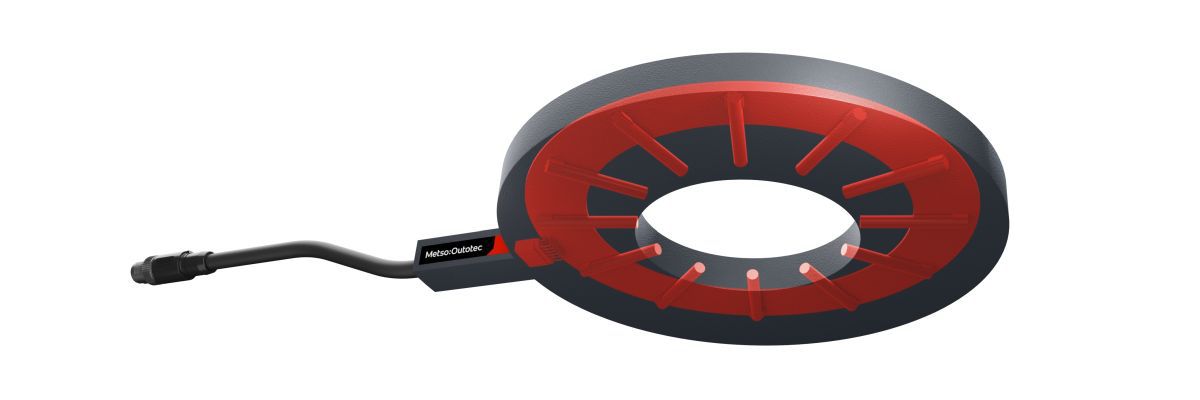

Metso Outotec Courier 8XL SL analyzer

Metso Outotec Courier 8XL SL analyzer

© Metso Outotec

“Courier® 8X SL will replace Courier® 8 SL in our automation portfolio. The previous generation Courier® 8 SL analyzers can be easily upgraded to Courier® 8X SL with the replacement of some main components,” says Juhani Rihtniemi, Senior Product Manager, Automation, Services at Metso Outotec. Metso Outotec also offers Lifecycle Services (LCS) for the Courier 8X to ensure the highest possible availability and measurement accuracy for the analyzer equipment. LCS combines available spare parts, maintenance and calibration expertise with market-leading digital monitoring and support tools, such as Metso Outotec Metrics supported by Performance Center services.