Metso Outotec launches Planet Positive Filtration Plant Units for sustainable performance

28.07.2022Metso Outotec is launching a comprehensive Filtration Plant Units offering to maximize operational reliability in different types of dewatering applications where superior process performance combined with energy and water efficiency is required.

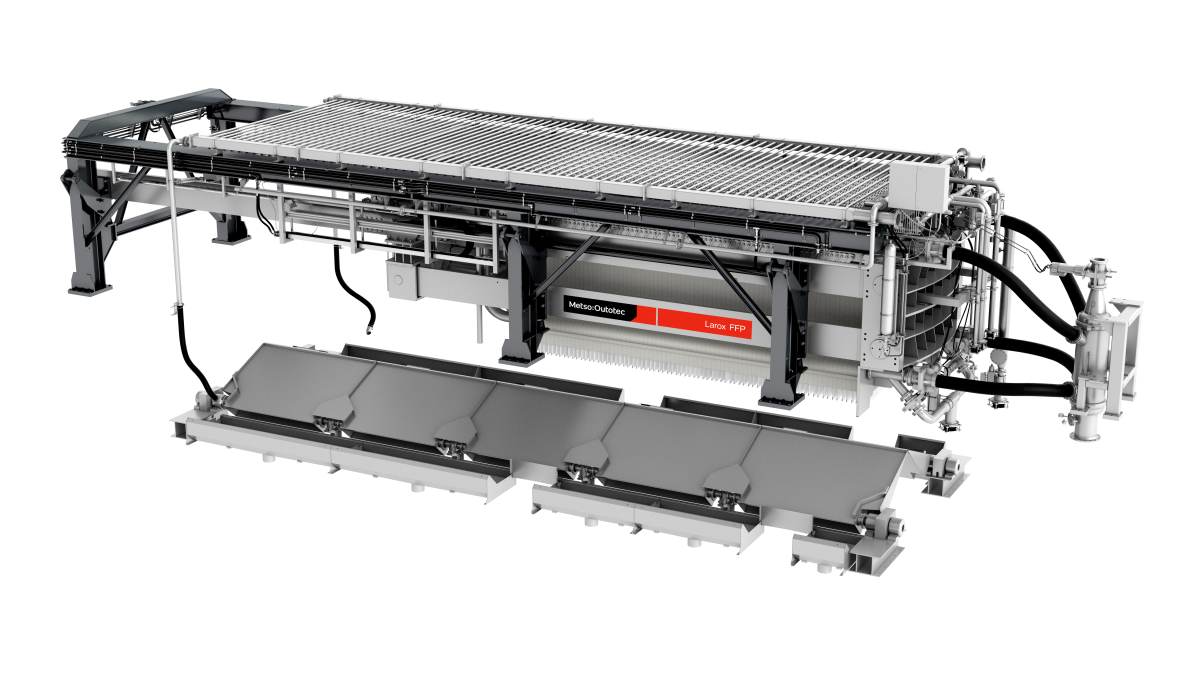

Metso Outotec Larox FFP3716 Filtration Plant Unit

Metso Outotec Larox FFP3716 Filtration Plant Unit

© Metso Outotec

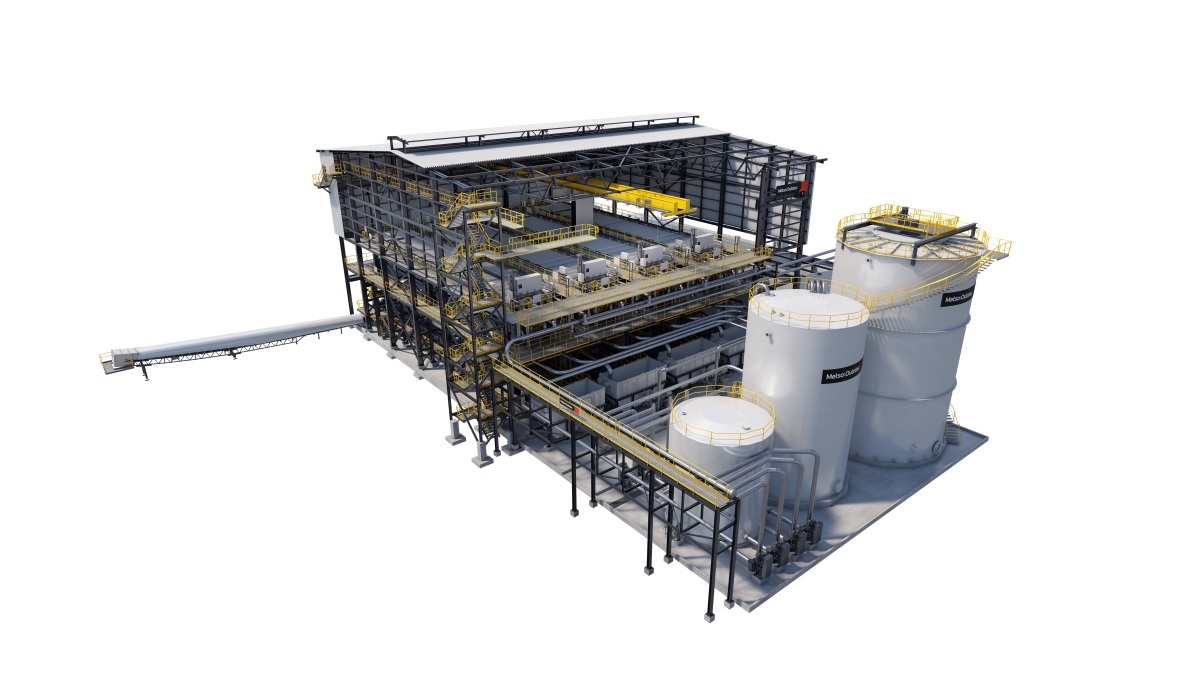

The offering consists of three major plant units around Metso Outotec’s Larox® PF and Larox® FFP, and Metso Outotec CC filter technologies, all designed for the dewatering of concentrates and tailings. The latest addition to the offering is the Larox® FFP3716 Filter Plant Unit, which represents the most advanced technology for the safe high-volume processing of tailings. All Metso Outotec Filtration Plant Units are scalable and come as complete customizable solutions to meet even the most stringent customer requirements.

“We have been supporting our customers with filtration solutions for almost 100 years. Today, our selection of filtration technologies is the largest in the field, and their energy, emission, and water efficiency is in a league of its own. The Filtration Plant Units combine all this knowledge to provide our customers with unrivalled dewatering performance,” says Toni Kuisma, Product Manager, Filtration Plant Units at Metso Outotec. He continues: “We have also optimized the engineering and delivery process. The new plant unit concept provides the fastest time-to-volume for our customers. Special attention has also been paid to the units’ maintainability through, for example, advanced digitalization. Their high level of automation enables easy optimization and remote support.”

The Metso Outotec Filtration Plant Units consist of advanced filters, screens, filter feed tanks, slurry pumps and conveyors coupled with process control system and various ancillary products and expert services, supported by Metso Outotec Dewatering Technology Center (DTC) in Lappeenranta, Finland. The integrated service offering provided by the company’s global network ranges from filter inspection and dewatering optimization to spares and wears and remote support and Life Cycle Services.

Core benefits

· Offering from equipment to turnkey supply of plant units

· Compact footprint and minimized elevation

· Pre-engineered package for faster project execution

· Process guarantees to de-risk customer’s investment

· Safe & superior plant design using industrial best practices

· Integrated service offering with global network

· Testwork capabilities with strong focus on innovation and R&D

· Automation and digital tools