Minerita selects Metso’s energy-efficient comminution equipment for its Compact iron ore project in Brazil

27.10.2025Minérios Itana Ltda (Minerita) has selected Metso to supply all key comminution equipment for its greenfield Compact iron ore project located in Itatiaiuçu, Minas Gerais/Brazil. The plant aims to produce 4.5 Mt/a of high-grade premium pellet feed in two phases.

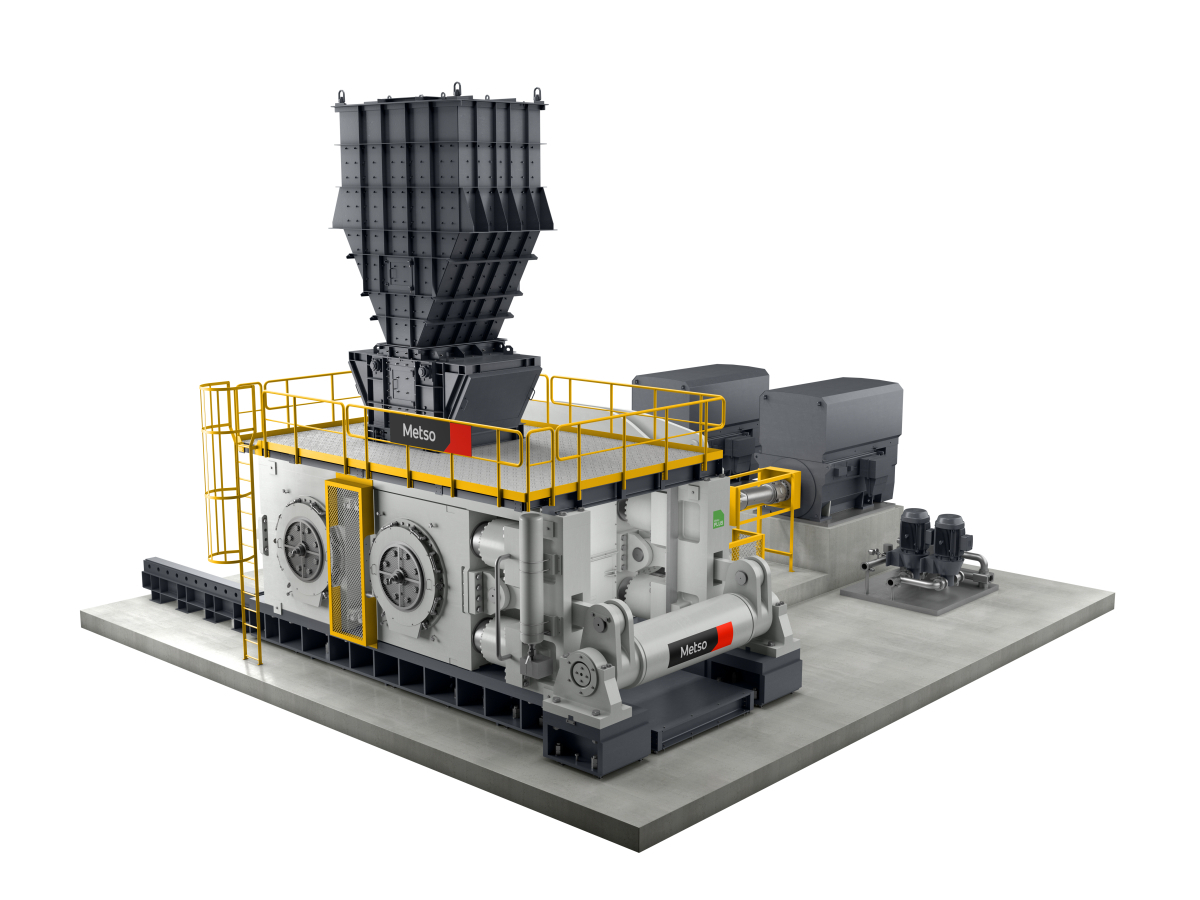

Metso Nordberg MP800 cone crusher

Metso Nordberg MP800 cone crusher

© Metso

The energy-efficient comminution circuit for the first phase will process compact itabirite iron ore and will consist of a Nordberg® C160™ jaw crusher, followed by a Nordberg® MP800 cone crusher, an HRC™e high pressure grinding roll (HPGR) and a 3.9 MW Select™ ball mill for primary grinding. Regrinding will be done with two Vertimill® VTM4500 stirred mills. The Vertimill® order has been booked in Minerals’ 2025 third-quarter orders received, and the rest in Minerals’ 2025 first-quarter orders. The value of the orders is not disclosed.

“The investment reflects our long-term collaboration with Metso on the Compact project. Initial contact was made already around 2010, and the close collaboration was key in selecting Metso as the partner for this energy-efficient comminution circuit. Recently, we had also purchased two Metso Larox® FFP3512 pressure filters for our tailings dewatering system to improve our existing dry stacking process and to enable a more sustainable and modern tailings management. These investments are aligned with our strategic objectives and our values, notably those of always doing things simply and doing them well, and valuing safety and sustainability,” explained Mr. Diego Reis, General Manager of projects and maintenance, and Mr. Lcio Cerceau, Process General Manager at Minerita.

Metso HPGR

Metso HPGR

© Metso

“This order is a great example of how our customers are embracing more energy-efficient and sustainable comminution flowsheets,” said Christoph Hoetzel, Senior Vice President, Grinding at Metso. “The now selected Vertimill® stirred mills and high pressure grinding roll technology are part of the Metso Plus portfolio, offering a more energy-efficient and sustainable way to grind ore, while also helping to reduce the operational costs and improve process performance through enhanced particle size control and reduced water consumption.”

Minerita’s order contributes to the rapid expansion of Metso’s global HPGR installation base, reinforcing the growing demand for sustainable comminution solutions. Through its comprehensive comminution solutions and extensive services, Metso offers grinding solutions with optimal configurations to customer-specific operational conditions, thereby enhancing energy efficiency, availability, and reliability.

Read more about Metso’s solutions for grinding here .