Over a half-million mark and still counting

04.11.2019Since 2016, the Rockster impact crusher R1100DS has been a valuable asset in processing asphalt, construction debris and gravel at Urschitz in Carinthia. It has meanwhile produced astounding 500 000 t of material. Bruno Urschitz GmbH from Finkenstein/Austria is a progressive family business with over 170 employees, and a state-of-the-art fleet of trucks, excavators and construction machinery. "Whether sand, gravel, grit or humus – we are the right partner for all kinds of construction projects," says Bruno Urschitz. The continuous growth of the company is also reflected in the wide range of services ranging from transport, earthmoving, recycling or gravel pits to their own filling station.

Ingenious screening system was a deciding point

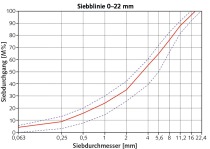

Because of the increasing demand for smaller product sizes in 2015, especially in road construction, where an asphalt fine planing material of 0/16 or 0/22 is preferred, Bruno Urschitz decided to purchase a new crusher. "My focus was on the R1100DS, but the screen surface was too small for me. Rockster has therefore designed a new screen box with 3100 x 1350 mm, so even with product size below 22 mm, we can achieve a good throughput. I especially like the stockpile function of the return belt. Because of it, we produce two fractions in one pass, which we use above all in the gravel pit. In addition, I can transport the machine with the screening system without extra hassle and since we use the machine 70 % on site, cost effective transport and low weight play an important role," says Urschitz.

R1100DS impact crusher for asphalt recycling

Rockster crusher shows its strengths especially in the recycling of asphalt and demolition debris. Mario Dreier has been working with the machine since the first minute: "I crush 80 % asphalt with the Rockster crusher and have now reached about 4000 operating hours. Because the bitumen in the asphalt becomes very sticky in the heat, I have to wash the cooler and the hydraulics after every third job. Of course, asphalt is generally a burden on the machine and the fine asphalt dust settles everywhere. But our Rockster does not let us down. For the most part, customers want 0/22 mm final product and for this size our impactor produces on average 140 t of final material per hour with a feed size of 0/600 mm on average and a fuel consumption of well below 40 l/h."

Ready for the job in 11 minutes

Mario Dreier does not only transport his crusher with his truck, he is also operating the excavator. "From unloading the machine to the first bucket, it takes exactly 11 minutes. If I have to readjust the crushing gap, add 4 minutes more. If a customer wants several product sizes, I change the meshes in no time thanks to the lowerable main belt and the quick-change system. So you can really be fast and efficient at work. That’s what I really enjoy when working with the R1100DS. If, for example, an iron part gets stuck between the main belt and the magnetic separator, I just lower the main belt and it’s right there. This function is very useful," says the operator.