Dry processing ● Dry Jigging of Coal

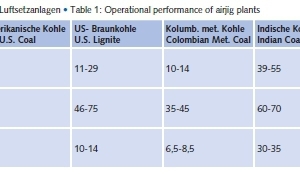

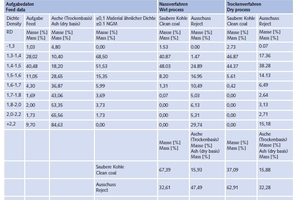

Summary: The first of the newer generation dry jigs has been commissioned in 2002 in the USA and more than 70 followed in recent years. This paper describes the advantages of the dry jig process. It also presents operating results from several dry coal beneficiation plants in the USA, India, Columbia, Spain and Turkey.

1 Introduction

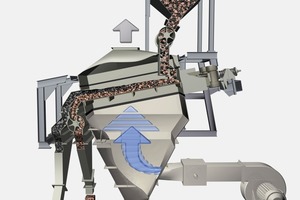

There are a number of advantages for upgrading coal with dry jigging technology, most notably the lack of process water, which eliminates the need for fines dewatering and slurry confinement. Dry jigging eliminates the product moisture penalty associated with wet processing of thermal coals. Particulate emissions are virtually nonexistent due to inclusions of fabric dust collectors on all modern dry jig plants. Due to the environmentally kind nature of dry jig plants, installation permits are often measured in days, not months. Coupled with all this advantages there has been a...