Cost reduction thanks to clean conveyor belts with REMACLEAN cleated belt brushes

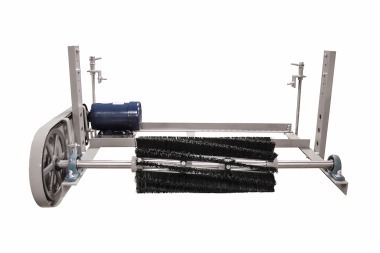

In this case, a conveyor belt cleaning system has been specially developed for cleated and chevron belts. The electrically driven brush system rotates against the running direction of the conveyor belt, thus cleaning its carrying side. The brush body is fitted with bolted combs made of polyurethane, which ensures fast and easy maintenance. Thanks to a standard and an HD version of the combs, belts with cleat heights of up to 32 mm can be cleaned.

To achieve the best results for almost every application, the product portfolio has grown in recent years and is constantly being improved. Thanks to years of experience and further development, cleaning systems can be offered for every area of application on the conveyor belt: Systems for use on the drum, for cleaning the lower belt, inner belt scrapers, as well as cleaning brushes. In order to be flexible, a wide variety of scraper materials such as rubber, polyurethane and highly abrasion-resistant hard metals are in use.

Brush maintenance and replacement without disassembly of the shaft

REMA TIP TOP was able to score with the innovative cleated belt brush solution with screwed cleaning combs made of polyurethane – REMACLEAN SGB-PUR. The system offers a longer service life of the brush combs while maintaining high cleaning quality. The proven brush now lasts twice as long and needs to be replaced after 2 years at the earliest.

Another major advantage of the SGB-PUR is the fact that time-consuming disassembly of the shaft is no longer necessary – thanks to the screwed brush combs. The replacement brush combs can be mounted without dismantling the complete system.