20.09.2013 / ABB to launch service product for continuous hoist monitoring

ABB launches a new service product for hoist systems: Hoist Performance Monitoring Service. With this state-of-the-art solution ABB experts can monitor and analyze the hoist system remotely. Furthermore, regular monitoring ensures that possible failures are detected before causing severe problems. This new product delivers a service that is unique in the underground mining market.

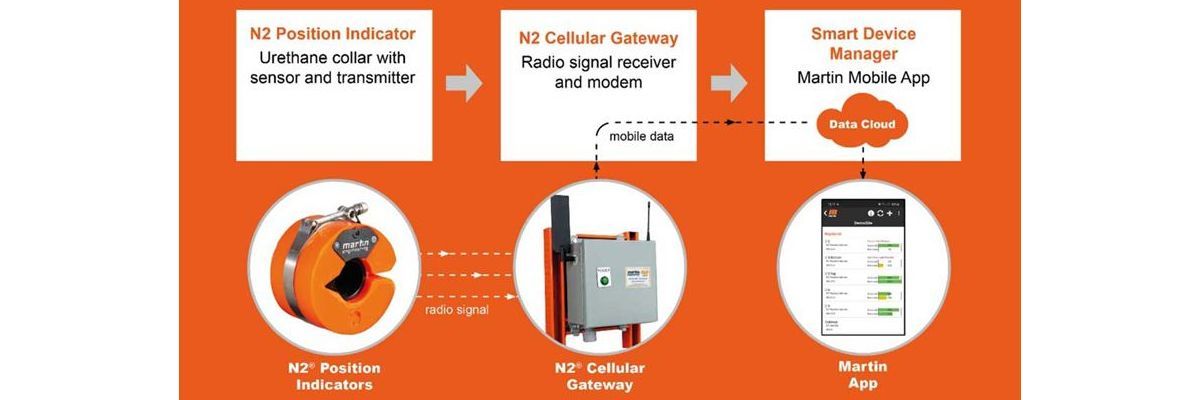

A mine hoist system is an extensive investment and an important component in the underground mining process. To get the most out of this investment, hoist systems must operate at the highest level of reliability and safety, as any potential failure can lead to catastrophic results. ABB’s Hoist Performance Monitoring Service connects customers’ hoist system to experienced ABB experts to monitor and analyze the hoist’s condition and performance. The new service links hardware monitoring with secure remote access options and expert software. It contains two solutions to maintain the hoist performance:

·Hoist service experts provide a scheduled quarterly analysis of collected data against established key performance indicators (KPIs). By utilizing remote sessions with ABB engineers corrective actions can be implemented. After every analysis the customer gets an associated report.

·ABB offers continuous asset monitoring over extended periods of time: If the monitored hoist system shows abnormal conditions, pre-established triggers alert the customer immediately. ABB proactively investigates the source of the alarm and provides recommendations to restore process performance.

Powered by ServicePort™, ABB’s state-of-the-art service delivery platform, Hoist Performance Monitoring Service uses non-stop data collection and analysis to transform raw data into actionable information, quickly pinpointing issues so that the hoist operator can ensure optimal performance of equipment and systems. ServicePort™ enables the retrieval of information from numerous operational points, including the hoist’s motor, hydraulics and brakes and helps to diagnose and identify root cause problems. With Hoist Performance Monitoring Service ABB sets new standards in maintaining hoist systems. Due to the state-of-the-art remote access this new service product is unique in the underground mining market. It allows site engineers to continuously collaborate with ABB experts whenever support is needed.