Europe's largest deposit of rare earth metals is located in the Kiruna area

12.01.2023LKAB has identified significant deposits of rare earth elements in the Kiruna area, metals which are essential for, among other applications, the manufacture of electric vehicles and wind turbines. Following successful exploration, the company reported mineral resources of rare earth metals exceeding one million tonnes of rare earth oxides and the largest known deposit of its kind in Europe.

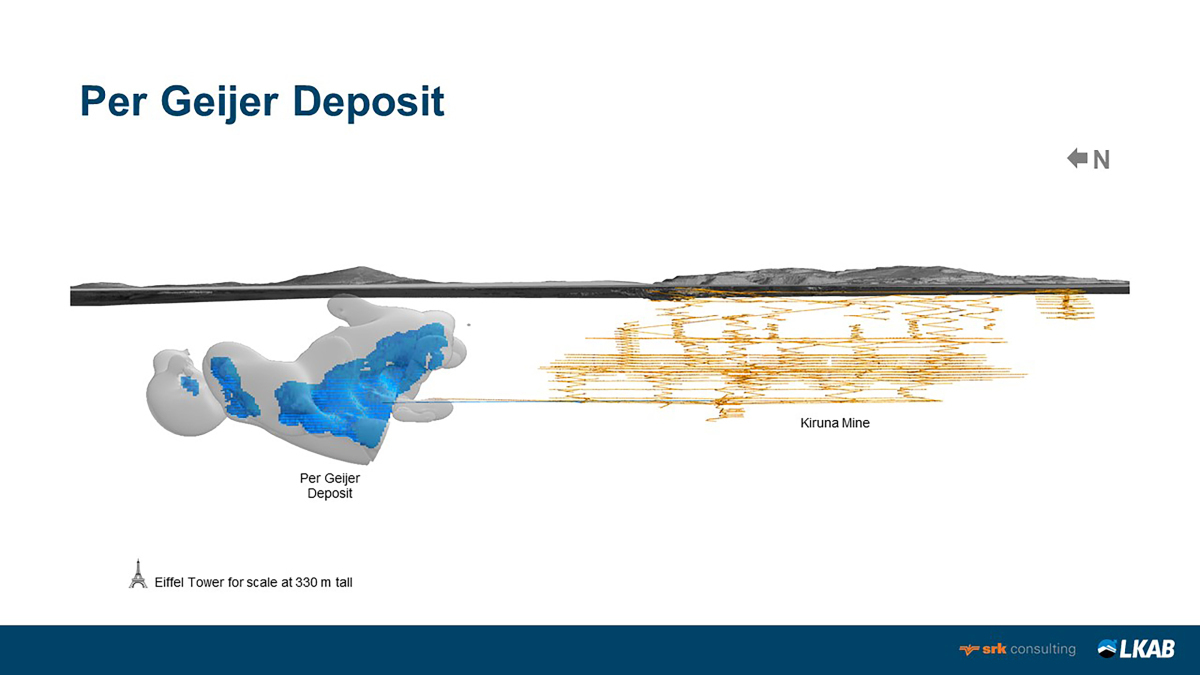

The Per Geijer deposit and the Kiruna mine

The Per Geijer deposit and the Kiruna mine

© LKAB und SRK Consulting

"This is good news, not only for LKAB, the region and the Swedish people, but also for Europe and the climate. This is the largest known deposit of rare earth elements in our part of the world, and it could become a significant building block for producing the critical raw materials that are absolutely crucial to enable the green transition. We face a supply problem. Without mines, there can be no electric vehicles," says Jan Moström, President and Group CEO, LKAB.

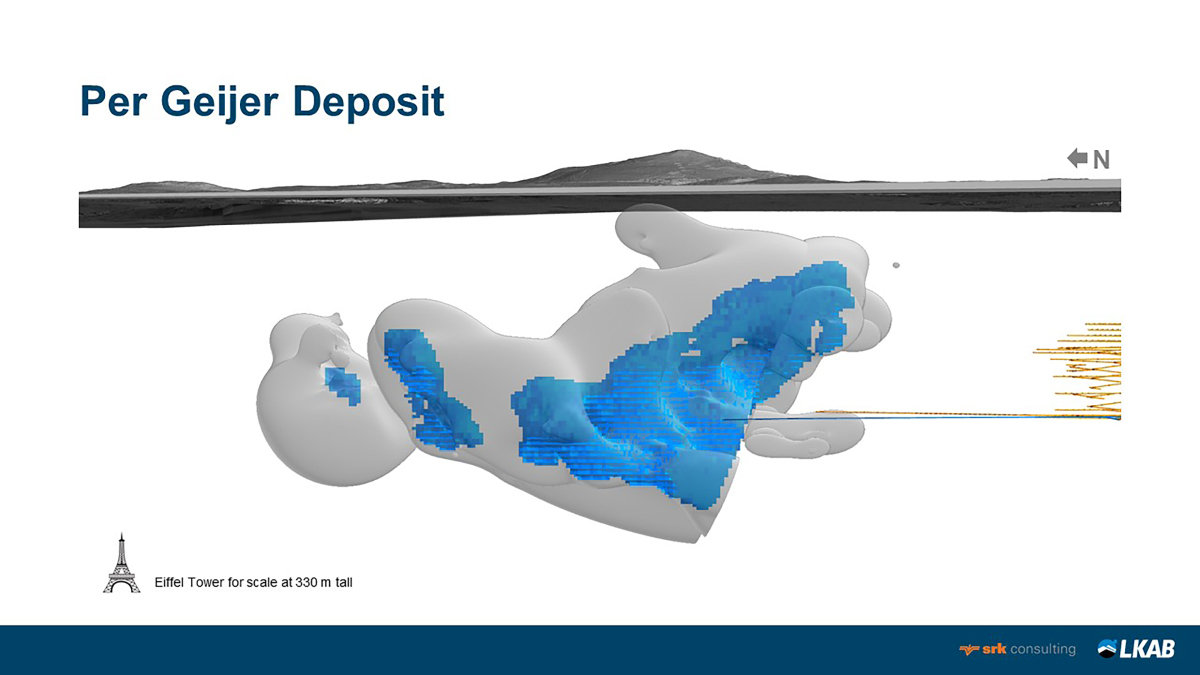

The Per Geijer deposit in relation to the Eiffel Tower

The Per Geijer deposit in relation to the Eiffel Tower

© LKAB und SRK Consulting

No rare earth elements are currently mined in Europe, at the same time, demand is expected to increase dramatically as a result of electrification, which will lead to a global undersupply, and this at a time of increasing geopolitical tensions. According to the European Commission's assessment, the demand for rare earth elements for electric cars and wind turbines, among others, is expected to increase more than fivefold by 2030. Today, Europe is also dependent on imports of these minerals, where China completely dominates the market, a factor which increases the vulnerability of European industry.

Town map of Kiruna region

Town map of Kiruna region

© LKAB und SRK Consulting

“Electrification, the EU's self-sufficiency and independence from Russia and China will begin in the mine. We need to strengthen industrial value chains in Europe and create real opportunities for the electrification of our societies. Politics must give the industry the conditions to switch to green and fossil-free production. Here, the Swedish mining industry have a lot to offer. The need for minerals to carry out the transition is great”, says Minister for Energy, Business and Industry, Ebba Busch.

Jan Moström, President and Group CEO of LKAB, with Ebba Busch, Minister for Energy, Business and Industry

Jan Moström, President and Group CEO of LKAB, with Ebba Busch, Minister for Energy, Business and Industry

© Wesley Overklift, LKAB

A long road to a mine

At the same time, the road to possible mining of the deposit is long, where the first step is an application for an exploitation concession for the Per Geijer deposit in order to be able to investigate it further at depth and investigate the conditions for mining. The plan is to be able to submit an application for an exploitation concession in 2023.

LKAB has already started to prepare a drift, several kilometres long, at a depth of approximately 700 m in the existing Kiruna mine towards the new deposit in order to be able to investigate it at depth and in detail.

We have not seen the full extent of the deposit.

"We are already investing heavily to move forward, and we expect that it will take several years to investigate the deposit and the conditions for profitably and sustainably mining it. We are humbled by the challenges surrounding land use and impacts that exist to develop this into a mine and that will need to be analysed to see how to avoid, minimize and compensate for it. Only then can we proceed with an environmental review application and apply for a permit," says Jan Moström.

"If we look at how other permit processes have worked within our industry, it will be at least 10 to 15 years before we can actually begin mining and deliver raw materials to the market. And then we are talking about Kiruna, where LKAB has been mining ore for more than 130 years. Here, the European Commission's focus on this issue, to secure access to critical materials, and the Critical Raw Materials Act the Commission is now working on, is decisive. We must change the permit processes to ensure increased mining of this type of raw material in Europe. Access is today a crucial risk factor for both the competitiveness of European industry and the climate transition," says Jan Moström.

Per Geijer – potential to become Europe's most important mine for critical raw materials

Promising results from LKAB's ongoing exploration in Kiruna and Gällivare were presented last spring. The deposit Per Geijer is in close proximity to existing operations in Kiruna. More extensive studies show an increase from 400 million tonnes of mineral resources with high iron content to over 500 million tonnes, and that the Per Geijer deposit contains up to seven times the grade of phosphorus as the orebodies that LKAB mines in Kiruna today. Phosphorus is one of three nutrients in mineral fertilisers necessary for food production and is on the EU's list of critical minerals.

Now, for the first time, LKAB reported a Mineral Resource and further extensive studies in Per Geijer of assets amounting to more than one million tonnes of rare earth metals in the form of Rare Earth Oxides, which are used to produce Rare Earth Elements (REE). This would be sufficient to meet a large part of the EU's future demand for manufacturing the permanent magnets that are needed for electric motors in, among other things, electric vehicles and windpower turbines.

The results are presented in accordance with the reporting standard PERC 2021, which is the prevailing international standard for LKAB.

The rare earth elements in Per Geijer occur together with phosphorus in the mineral apatite, in what is mainly an iron ore deposit and which may therefore be produced as by-products. It also creates completely different opportunities for possible competitive mining.

"LKAB is already planning a circular industrial park in Luleå with new technology for the extraction and processing of phosphorus, rare earth elements and fluorine based on today's existing mining production. There, instead of landfilling the material, it can be used to create new, sustainable products. A production start is planned for 2027," says Leif Boström, Senior Vice President, Business Area Special Products, LKAB.