Record Metso filter service orders in the Americas markets

16.08.2023Metso has been awarded repeat orders for filter modernization, plate packs, and related services from several major mining companies in the North, Central and South America markets. In addition to the filter modernization, several larger modernization orders for other types of dewatering solutions have been booked. By utilizing Metso’s expertise and technology, customers will be able to increase uptime and achieve capacity improvements.

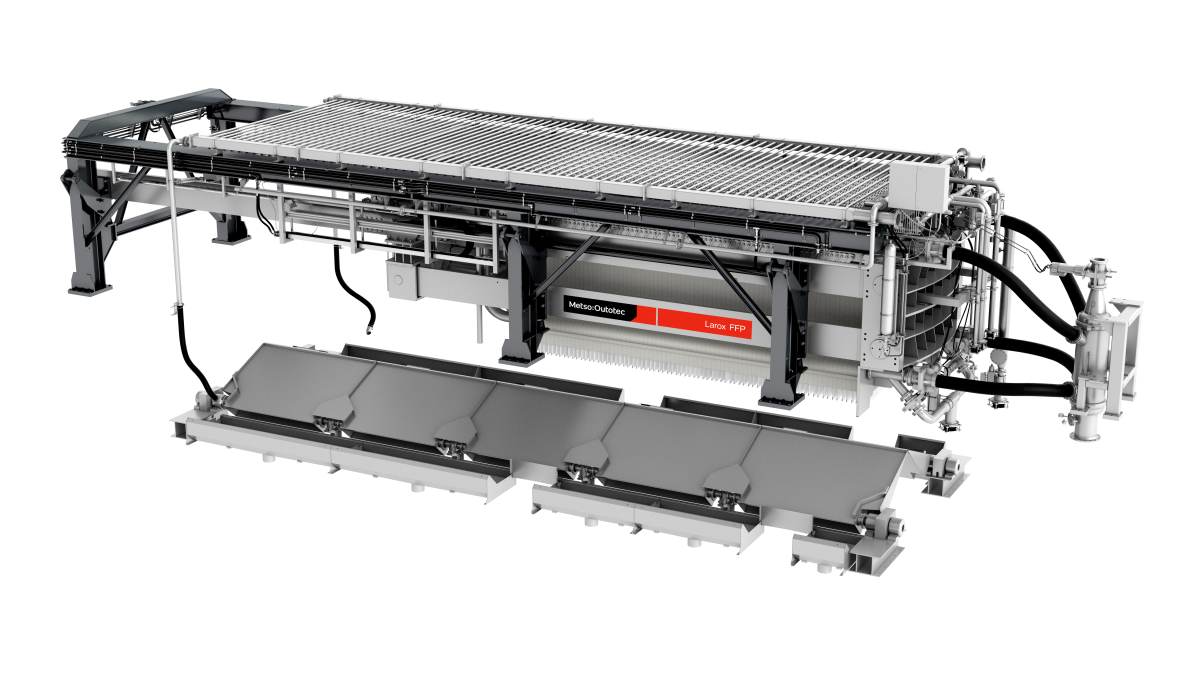

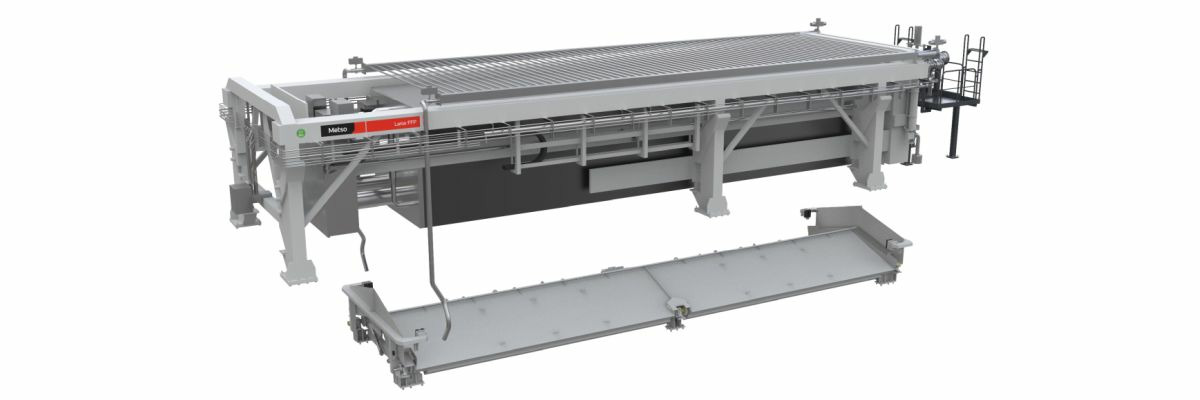

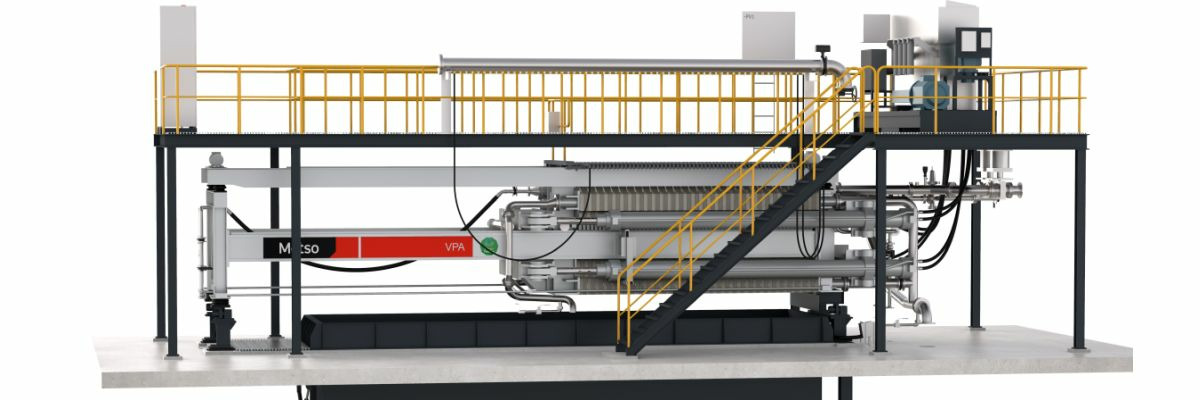

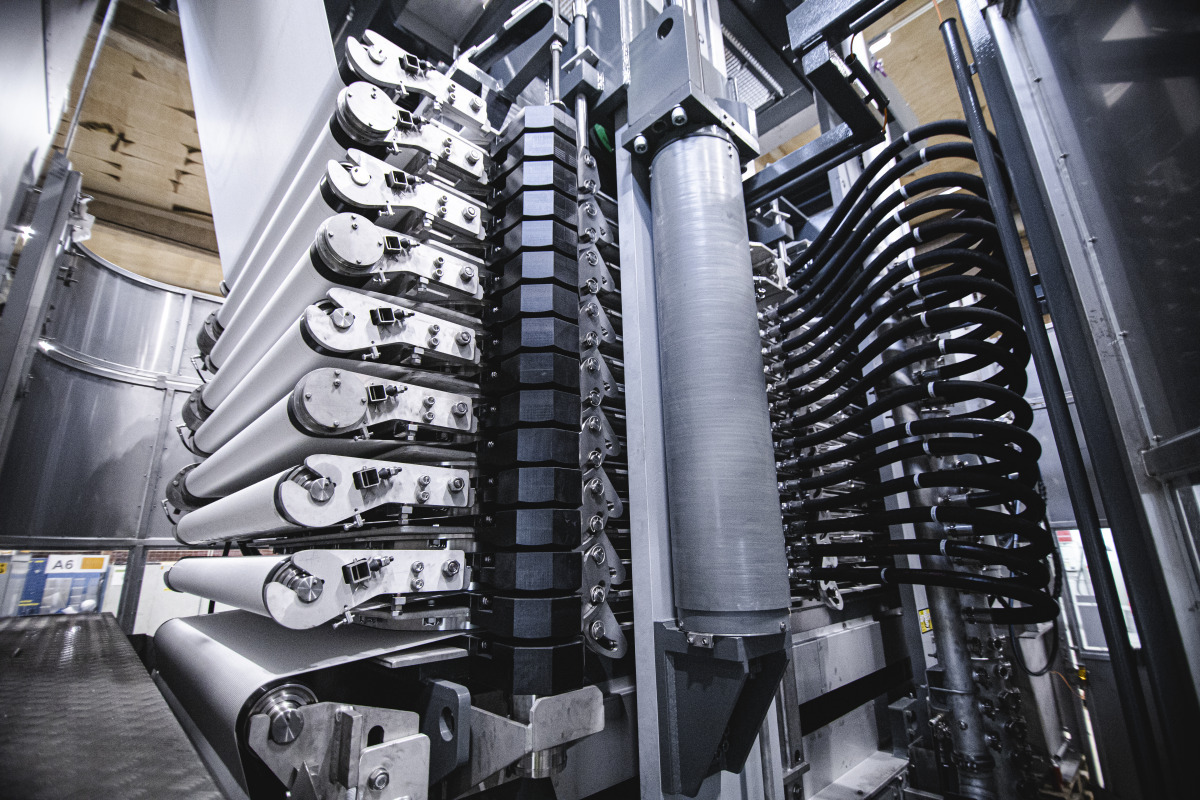

Metso's filtration technology

Metso's filtration technology

© Metso

The value of the orders amounts to more than € 15 million, of which 70 % was booked in the Minerals segment’s first quarter, and the rest in the second quarter of orders received. In the first quarter, Metso received the largest filter modernization order in its history, totaling EUR 10 million. The company’s largest thickener modernization order was also booked in the first quarter.

“The customer interest and need for high-quality filters, filter spares, and services are rising. We are very glad to confirm several repeat orders with our key customers. The new polymer filter plate factory in Mexico is an important investment, and it will increase our capability of meeting customers’ demands, simultaneously strengthening our strong position in mining concentrate and tailings filtration solutions,” says Tomas Hakala, Senior Vice President, Beneficiation, Dewatering, and Hydrometallurgy Services business line, Metso.

From the new factory, Metso will provide customers with shorter lead times and transportation distances, especially to the Americas. The first filter plates are expected to be manufactured in the second half of 2024, and full production capacity is expected in the end of the first half of 2025. Once fully operational, the factory will have the capacity to serve the full filter portfolio.

Metso’s filtration portfolio consists of 15 different filter types and comprehensive services for hundreds of applications. More than 80 % of Metso filters are part of the company’s Planet Positive portfolio, primarily thanks to their efficiency in the recovery and reuse of water. The company has carried out more than 14 000 filtration tests and delivered more than 5000 filters for various applications worldwide. Many of the filters are sold under the Larox® product name along with Metso corporate branding. Read more about filtration on our website.