Agglomerated

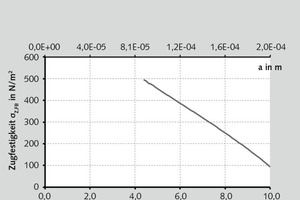

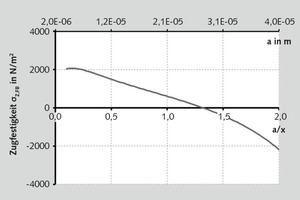

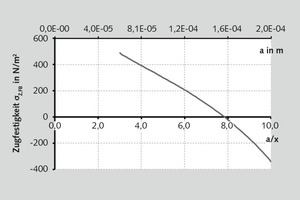

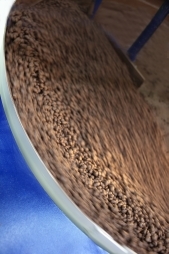

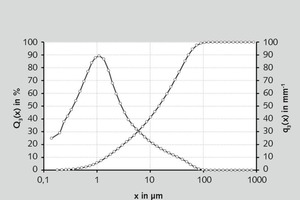

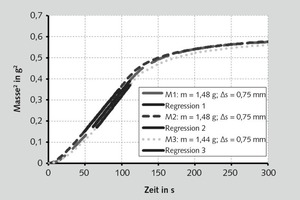

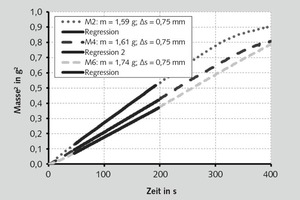

Wetting behaviors of mineral secondary raw materialsSummary: Construction waste (Fig. 1) is recycled through agglomeration in a pan granulator. Spherical agglomerates smaller 10 mm are formed which are recycled as aggregates for concrete. Important for agglomeration are the wetting properties of the powder with water, including in the contact angle. Brick material with known porosity is formed. Subsequently, the contact angle is determined by the modified Washburn-method.

1 Assignment

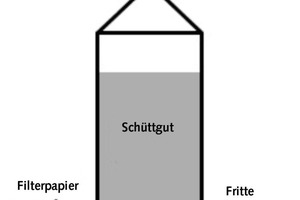

The following article examines the accumulation agglomeration of mineral secondary materials. A pan granulator is used for accumulation granulation and continuously generates spherical agglomerates of only slightly varying particle size. Water is used as the binder, and is injected into the pan granulator by means of dual-fluid nozzles. This water wets and moistens the primary particles and the as yet incompletely agglomerated granulates. Liquid bridges between the individual particles cause them to adhere to one another and thus agglomerate. Masonry (brickwork) rubble yielded by...

![6 Modell einer Flüssigkeitsbrücke zwischen zwei gleich großen Kugeln; Pietsch [3] # Model of a liquid bridge between two spheres of identical size; Pietsch [3]](https://www.at-minerals.com/imgs/tok_f8cac2114ad901f52fdf3f160a00246d/w300_h200_x400_y487_101311941_87becb3c99.jpg)