Centrifuges for the world market

In September, Siebtechnik GmbH took the completion of its new Technology Centre as the occasion to present to the trade press not only its ultramodern production line for centrifuges (Fig. 1), but the redesigned office and administration building too (Fig. 2). The newbuild project was realized in a relatively short time – 3 months of planning and 16 months of construction – and from an architectural perspective it presents a well-accomplished integration of modern building fabric in an existing structure (Fig. 3). The new assembly facility (Fig. 4) covering a total area of 2800 m² is equipped with a 500 m² paint shop. The offices have been extended from 760 m² to around 2200 m². Here are also generously sized event and training facilities in which the company can offer internal and external advanced training courses in future.

Before the tour of the new facilities, the Siebtechnik management, represented by Christian Steinhaus, Horst Dietschreit and Karl Bongartz (Fig. 5), informed the press representatives about strategic and technical news in the group of companies. Other topics discussed included ongoing large-scale projects and the future direction of Siebtechnik GmbH.

Strategic development of the company

Siebtechnik GmbH, founded in 1922, is part of the globally operating Stafag group of companies, which employs approx. 3500 people in around 50 individual companies. The group also includes Steinhaus GmbH, Hein Lehmann GmbH, Isenmann Siebe GmbH as well as TEMA Holding NV, which was set up back in the 1920s as a foreign sales company with the aim of developing new markets.

Within the group, Siebtechnik GmbH has established itself as an innovative supplier especially for highly specialized solutions in solid-liquid separation with a very wide range of centrifuges – including the largest centrifuges in operation worldwide. With this range of products, the company generates around 70 % of its sales; the remaining 30 % are distributed between the traditional manufacturing area for screens and manufacturing for the laboratory and sampling segments.

The current strategic development in the company is shaped by the globally growth-oriented investment policy. Besides the expansion of the headquarters in Mülheim an der Ruhr/Germany (Fig. 6), over the last three years the company has set up a new plant in Wuqing, Tianjin/PR China and expanded an already existing plant in Cincinnati, Ohio/USA (Fig. 7). Here, in addition to centrifuges for the chemicals and foodstuffs industry, coal centrifuges are manufactured and shipped worldwide, for example, to China, Russia or Africa. Moreover, the group of companies has made other extensive investments in new production plants in Germany – plant extension for the sister company Isenmann in Karlsruhe, where polyurethane screen decks are manufactured – and in a service and repair company Tema Engineers in Australia.

At present the focus is on stepping up cultivation of the Russian market. Following the recruitment of technically and linguistically qualified staff, the company is now continuously supplying centrifuges manufactured in the USA to the Russian coal industry. In addition, other orders from the field of bulk solids sampling could be won. In July 2014, a sampling plant for ore was delivered to Russia, a current major contract with a delivery date in 2015 concerns the sampling of fertilizer.

The mining industry in South Africa is supplied by Siebtechnik GmbH. In Johannesburg there’s a site with around 1100 employees which is responsible for the entire English-speaking African market. The French-speaking African market is looked after from Europe.

Specialist for special solutions

In the early 1990s, the management at Siebtechnik GmbH decided to specialize on the manufacture of centrifuges for special solutions in the foodstuffs and chemicals industry. Accordingly, the focus was on the new and further development of centrifuges, especially their adaption to specialist applications. In the meantime Siebtechnik GmbH manufactures the widest range of centrifuges in the world – with ten different types of centrifuge in ten different sizes and many patented design variations as well as the highest capacity centrifuges, and with this range it has established itself as one of the technology leaders in this sector.

As a logical consequence of these past successful 25 business years, the new Centrifuge Technology Centre (Fig. 8) and the extension of the office and administration building have now been realized. Goal was to merge and closely link the entire value creation chain: from development and design, material procurement and manufacturing to sales and service – everything is concentrated at the company’s facilities. Part of production that had been previously contracted out has also been integrated at the headquarters, for with the new technology centre the structural and technical preconditions have been created to manufacture even the largest-capacity centrifuges in-house. In addition, the extended building complex provides more space for internal communications (Fig. 9), to push ahead with new developments and production processes through the creative exchange of ideas.

One of the most successful developments in past years is the HSG 1650 vibratory centrifuge (Fig. 10) – according to the company, the highest-capacity centrifuge in the world. This centrifuge is used to process coarse-grained or easily dewatered bulk solids, e.g. in coal or potash preparation (Fig. 11).

Mammoth project in China

Siebtechnik has been active in China since 1985, and in 2004, in a joint venture with Tema Holding/Netherlands, it established Tema Siebtechnik Process Equipment. A big order from China gave Siebtechnik GmbH a further boost to its current success story. When Quinghai Potash Production (QPP) in China asked whether the Mülheim-based company could supply large centrifuges with a throughput of 100 t potash per hour, the management said yes and took on the challenge (Fig. 12). Within just seven months, the engineers at Siebtechnik GmbH developed what was the up until then largest worm/screen centrifuge, type CX 1500, with a basket diameter of 1500 mm. After the centrifuge had successfully undergone three months of testing at the production site near the Tibetan border, in spring 2012 came the order for 40 large centrifuges with a value of € 20 mill. (Fig. 13).

Siebtechnik GmbH made up for the initial lack of capacity for processing this extensive project by renting a production facility from an associated firm and the re-employment of previously retired employees. The “former” employees threw themselves into the challenge with admirable dedication so that nothing stood in the way of the on-time delivery in October 2012. The customer’s satisfaction with the overall handling of the project led in March 2014 to a follow-on order for 20 more large centrifuges of the same type.

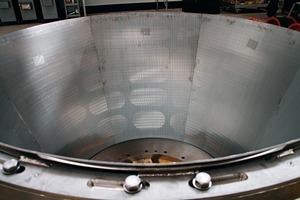

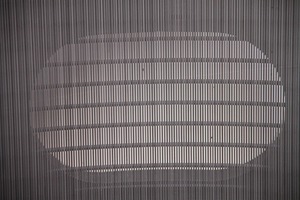

The design principle of the successful new development is based on a horizontal worm/screen centrifuge designed back in 1948, which was further developed under the product name CONTURBEX and used as one of the most versatile screen centrifuges for a wide range of separation duties. In the development of the CX model of this series, great importance was attached to process efficiency and machine reliability at high throughput rates. With a minimum of components (Fig. 14) and simplified design, both fast maintenance and, if required, the quick replacement of individual components are possible (Fig. 15).

During the plant tour at the trade press event (Fig. 16), the press representatives were able to inspect the different groups of components (Fig. 17 and Fig. 18). Some of the machines in this series were already at the final assembly stage and were being given the finishing touches before being sent to China to go into continuous operation at QPP (Fig. 19). An order for more large centrifuges is expected. To ensure service and maintenance of the large-size centrifuges at QPP, Siebtechnik GmbH employs an operative locally.

The special business relationship of Siebtechnik GmbH with China is also shown by the fact that around 30 to 40 % of the centrifuges produced in Germany are destined for the Chinese market. There are currently over 400 centrifuges made by the company in operation in China, for this reason there is a relatively high service and maintenance requirement. Consequently, Siebtechnik GmbH has extended the existing service centre and the built the new plant in Wuqing that went into operation in 2012 on a total area of 3800 m² (Fig. 20). In the state-of-the-art equipped plant, qualified Chinese employees produce not only different plant and replacement parts for the Chinese market. The company has also ensured that it is possible to manufacture Siebtechnik GmbH’s entire range of centrifuges, especially centrifuges to 1500 mm diameter, there.

Managing Director Horst Dietschreit is proud of the company’s success in the land of the rising sun: “We provide our customers in China with outstanding service that also meets German quality guidelines. Particularly important to us was the training of our Chinese employees – almost more important than the investment in the machinery. After all, the machines on their own are useless if the employees cannot operate them properly.”

The company is currently building up a large network of sales agents in China’s different provinces – also with Chinese staff. Recent sales successes confirm this strategy of Sieb-technik GmbH on the Chinese market. Also the product sector for automated sampling systems, used, for example, for sampling exported coal during ship loading, is playing an increasingly important role. Deliveries of turnkey plants to process primary samples to detailed analysis in the laboratory with an order value of up to € 5 mill., competently operated by qualified staff, are part of the day-to-day business for Siebtechnik GmbH.

//www.siebtechnik-gmbh.de" target="_blank" >www.siebtechnik-gmbh.de:www.siebtechnik-gmbh.de