New recycling facilities for the Hagedorn Group of companies: Hannoveraner Wertstoffzentrum and Hagedorn Hannover GmbH

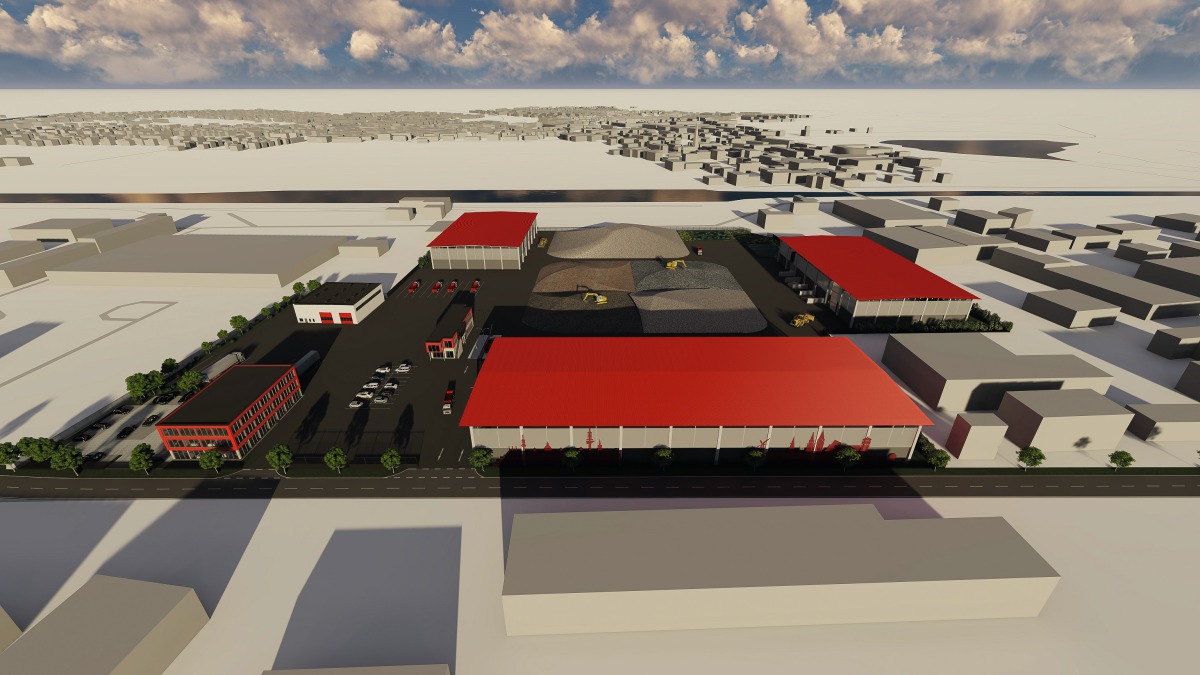

1 Visualization of the new site

1 Visualization of the new site

© Hagedorn

With the approval for the Hannoveraner Wertstoffzentrum recycling centre in October 2020, the Hagedorn Group of companies will in future increase its capacities for professional waste management and disposal in Northern Germany, too. Based in Hanover, HWG serves as operational support for Hagedorn’s central office in Hanover. “As a trimodal site, Misburger Harbour offers the possibility of material transfer between inland waterways, rail and road transport, which lowers transport costs and minimizes CO2 emissions associated with transport,” explains Alfred Winkelmann, Managing Director both of the recycling centre in Hanover (HWG) and in Gütersloh (GWG). This paves the way for even more sustainable waste management and disposal. The official ground-breaking ceremony has now symbolically marked the start of the construction phase.

Three recycling units, office and common rooms

Built at the site will be three recycling units covering a total area of around 13 000 m², for the treatment of mineral-based waste from landscaping and earth work as well as demolition projects. Also planned is a weighing terminal with office and common rooms. Operations are set to commence in autumn this year. At the Recycling Centre, 20 new jobs are being created, while 20 more jobs will be available at Hagedorn Hannover GmbH, the company also moving into a new facility at the site. Total investment in the project runs to around € 18 mill.

2 Left to right: Barbara Hagedorn, Managing Director of the Hagedorn Group of companies, Thomas Hagedorn, Managing Partner of the Hagedorn Group of companies and Alfred Winkelmann, Managing Director of Gütersloher und Hannoveraner Wertstoffzentrums GmbH at the new location at Misburg Harbour

2 Left to right: Barbara Hagedorn, Managing Director of the Hagedorn Group of companies, Thomas Hagedorn, Managing Partner of the Hagedorn Group of companies and Alfred Winkelmann, Managing Director of Gütersloher und Hannoveraner Wertstoffzentrums GmbH at the new location at Misburg Harbour

© Hagedorn

In future, HWG will serve as a recycling centre for mineral mixes and waste from dismantling, demolition, civil engineering and other construction projects. Thanks to it being part of the Hagedorn Group of companies as a full-service provider, HWG offers logistics, waste disposal and recycling services from one source. With the new recycling centre, HWG has the necessary capacities to respond to all market enquiries concerning waste management and disposal.

Recyclables must be returned to the production cycle

Because the requirements for waste management and disposal are becoming increasingly complex, it has become necessary to set up another recycling centre. “The more recyclables returned to the production cycle, the lower are the disposal costs and impact on the environment,” says Alfred Winkelmann. The managing director is convinced: “Recycling has long since arrived in the construction industry.” In his view, to achieve the sustainability goals set by society for 2030, a rethink was necessary in all construction segments. This concerned demolition as well as refurbishment or the construction of new buildings. “We have to move away from the throwaway mentality to recyclability,” stresses the expert. With the development of the HWG, the Hagedorn Group of companies has taken a step closer to achieving this goal.