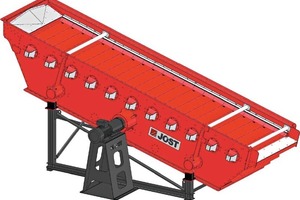

OSCILLA – the new dimension in screening technology

JÖST can also supply a multiple-deck Flip-Flow version and a combination screen where any type of screen deck can be used on the top deck - from PU panels to the JÖST Top-Spin cascade screen deck.

OSCILLA’s new technology allows an optimum and individual adjustment of the upper and lower screen deck. The available working widths are between 900 mm and 3000 mm, depending on the application, with screen lengths of up to 9000 mm. Dr. Petra Strunk, Editor-in-Chief of AT INTERNATIONAL, took the opportunity of this unveiling at the POWTECH to speak to Dr. Marcus Wirtz, Authorised Company Officer and Sales- and Marketing Director at JÖST GmbH + Co. KG, to learn more about the new Flip-Flow system.

Dr. Marcus Wirtz: The primary need for this technology is in screening sticky material which normally tends to blind the screen deck. These are often inhomogenous materials and those with a high moisture content.

Dr. Marcus Wirtz: In the Recycling Industry glass recycling is a typical example. Depending on the country and regions, the glass can have a high content of organics which makes screening with regular screens difficult or impossible. OSCILLA is an ideal solution in slag, ash and ASR processing. Furthermore any inhomogenous material, like in MRFs, industrial waste, RDF and materials from the German “Dual System” collection system are ideal applications.

In the minerals sector, we have achieved extremely good results in the screening of coal, coke, heavy moist sands and sticky soils.

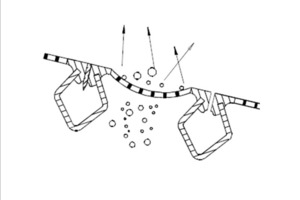

Dr. Marcus Wirtz: This is a two-mass system; it consists, on the one hand, of the machine body, with the screen frame installed inside as the second component. The fundamental principle is based on a circular motion screen, either via an unbalanced drive mechanism, or a shaft drive on the larger machines. Then there is the inner frame, which converts the circular motion into a linear motion. The two different movements – the oscillation of the machine body, and the linear oscillation of the inner frame – generate a pronounced up-and-down movement of the screen deck. The linear oscillation of the inner frame is generated by a newly developed leaf-spring system – this, in fact, is a unique feature of our system.

This new innovative system is an almost maintenance-free design, for which we have filed a patent. Wear is minimal, and the machines are extremely durable, since the leaf springs are only exposed to forces in one direction only, and the load is uniformly distributed across the groups of springs.

Dr. Marcus Wirtz: It enables us to achieve enormously high screen deck acceleration, of more than 50 G – an extremely high value. The particles are accelerated in different directions in this process, keeping the screening mats free (Fig. 3).

Dr. Marcus Wirtz: The retaining system in the cross members is extremely easy to install, and also extremely durable. It’s a JÖST design proven over many years. We’ve never had any problems with it even at these high accelerations.

The screen deck surfaces have raised edges to assure maximum screening area. A second advantage is optimum edge sealing. JÖST has developed extremely reliable solutions for this over the years. The screen deck surfaces can still be changed quickly and without difficulty, another benefit that users repeatedly emphasise.

Dr. Marcus Wirtz: That’s another great advantage of OSCILLA – the system is extremely flexible. Changes caused by variations in moisture levels, e.g. due to exposure to weather are balanced out automatically. The spring system is extremely easy and user-friendly to adjust if very different materials are to be screened by the same machine.

Another important factor is the insensitivity of this machine to temperature. The performance and motion remains the same, irrespective of very low or high temperatures. So nothing has to be changed on the machine, whether it’s operating in summer or in winter. The angle of attack can be adjusted via the drive mechanism. The line of action can be changed without changing the inclination of the machine. This is a big benefit and allows us to keep a much lower inclination.

Dr. Marcus Wirtz: We’ve already sold a number of machines, to the Recycling Industry, in particular.

Dr. Marcus Wirtz: Above all, we’ve noticed increasing demand for ever finer screening – we’re talking here about the 2 to 3 mm range. The danger of blinding of the screen deck rises proportionally to the moisture content. OSCILLA is an optimum solution to this problem. Integration costs are also an important factor, and the low machine height and the absence of a separate control system allow a quick integration at reasonable cost, even into existing installations.

Energy-efficiency is another important aspect: JÖST has always seen itself as a pioneer in this area, and has consistently been ahead of current standards. So we were naturally a member of the “Blue Competence Initiative” of the VDMA and had their certification from day one. OSCILLA is also available in multiple-deck and combination screen types – the decks are then arranged „stacked“ one above the other, so that the machine has an extremely small footprint. This solution is also considerably more energy-efficient than two individual screens.

Hall 1; Stand 451