Production of spiral fabric complements process belt expertise

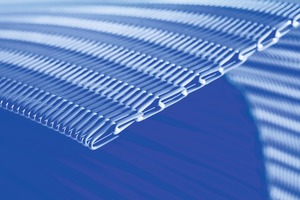

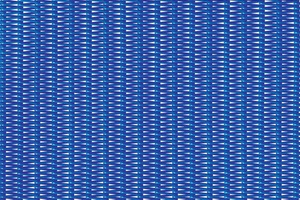

Now, GKD also produces and fixes the individual spirals application-specifically at its own works. Depending on the intended use, the spirals of round or flat wire can be equipped with antistatic properties or improved abrasion resistance. In the course of the production process, the spirals are linked into each other and joined using a pin wire into spiral fabric belts measuring up to 6 m in width. The linking and the connector give the screen belts stability and track accuracy. To increase the cross-stability even more or to equip the screen for deployment in a double-belt dryer with a magnetic support system, an additional pin wire made of magnetised steel is also an available option. Thanks to the specially formed filler wires worked into the spirals, GKD can specifically configure the air permeability of the screens to match the individual deployment scenario. For example, the aperture for sludge dewatering is equivalent to that of the tried-and-tested mesh type 1003. In contrast, for use in dryers the aperture is correspondingly larger. After the linking stage, GKD gives the unfinished screen its final properties as a spiral fabric belt through precision thermal treatment, cutting and edge sealing on both sides – all tailored to the individual case. The screens are delivered to the customer safely packed as rolls.

Spiral fabric belts are available from GKD as filter or dryer belts and also as transport belts. Up to six metres wide, produced seamlessly and cut to size, they excel through their consistently robust construction, their high degree of cross-stability and their resistance to mechanical strain. Application-specifically configured air permeability, track accuracy, high throughput performance and good product discharging properties make the new GKD spiral fabric belts – filled or unfilled – the premium choice for a wide range of applications where conventional woven mesh belts reach their limits.