TY-WIRE Hybrid Screens

When screening loose, bulk materials, and especially when handling abrasives products such as stone, gravel or crushed stone, screen decks are subjected to extreme loads. This leads to more frequent replacement of the wire mesh, which in turn results in undesirable downtime. An alternative is using polyurethane screen decks. Although they have longer lifetimes, they also have less open screen area and so there’s a loss of screening capacity. To compensate for this an additional screening machine often has to be put into operation.

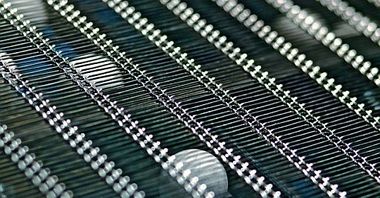

TY-WIRE Hybrid screening decks combine all the advantages of wire and polyurethane screening decks because TY-WIRE consists of wire mesh that is encapsulated in polyurethane using a special process. The result is a screening deck with a significantly greater open area when compared to conventional PU screening decks. At the same time, they have a lifetime that is 4 to 6 times longer than wire screen decks. TY-WIRE is available with opening sizes of 3 mm to 38 mm and can be used in screening applications with temperatures up to 70 °C. The conical screen openings prevent particles near the cut size from getting jammed. A clogging of the screening deck can be mostly eliminated. An additional advantage: TY-WIRE can be used without overhauling the screen deck. This applies with screen decks with modular insert systems and decks for screen sections. TY-WIRE screen decks with hook strips are screened in the same way as wire-screen decks. Modular designs are also available.