Turning things to your advantage: Kubria Cone Crushers now with an adjustable stroke

Flexibility makes all the difference: Modern plant concepts must include an option for flexibly adjusting crushers to changing requirements, such as varying throughput rates or feed material hardness. That’s why thyssenkrupp is now fitting all Kubria® cone crushers with an adjustable stroke. The adjustable stroke, which thyssenkrupp initially only offered for the Kubria 150 and Kubria 210 models, is now included as standard in all machines in the range, bringing the flexibility previously only available to users of large-scale mining machinery to the aggregate industry.

In the highly competitive market, maximum efficiency and low operating costs are critical for plant operators when processing aggregates or ores. To ensure this with different equipment configurations, the parameters of every machine involved in the process must be perfectly matched.

Kubria cone crushers from thyssenkrupp are modular and can easily be adapted to a wide variety of conditions. In addition to the usual options such as infinitely variable adjustment of the crusher gap, Kubria cone crushers also allow operators to change the stroke of the crusher shaft without needing to replace parts of the eccentric drive unit.

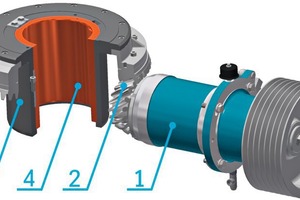

Fig. 2 shows the basic design of the eccentric drive unit. The eccentric bushing (3) is set in motion by the back gear (1) and spiral gear (2). The crusher shaft is guided by the eccentric bushing insert (4) and moved in a tumbling motion. The stroke of the tumbling motion is determined by the eccentric insert. The stroke influences not only the quality of the final product, but also the throughput rate and power consumption of the cone crusher. On many cone crushers, the stroke can only be adjusted by replacing the eccentric bushing insert or the entire eccentric drive unit.

To adjust the stroke, the eccentric bushing insert simply needs to be removed from the eccentric bushing and rotated. Once the insert has been re-inserted in the correct position, it is held in place by a key. The set eccentricity is determined by the position of the eccentric bushing insert relative to the eccentric bushing and can be clearly seen on the insert. A detailed description of this procedure is illustrated in Fig. 3. Since all work can be carried out from above, it only takes a short time and the adjustment can be made e.g. while replacing the crushing tools.

The adjustable stroke feature makes it possible to influence the following operating characteristics and adapt the Kubria cone crusher for:

Required throughput rate

Required product quality

Hardness of feed material

Maximum permissible power consumption

Using cone crushers with an adjustable stroke allows plant operators to adapt their processing equipment to changing conditions easily and flexibly. That saves time and money. The correct stroke setting ensures Kubria cone crushers fit perfectly into the overall system, allowing for uniform material flow while maintaining high throughput and excellent product quality.