Metso Outotec launches Filtration inspection packages to improve filter performance

23.08.2021Metso Outotec launched three Filtration inspection packages centered around offering improved filter availability, better filter performance and longer equipment life. The packages are designed to quickly identify common wear and tear issues such as problems with the plate packs, leakages, and misalignments among others.

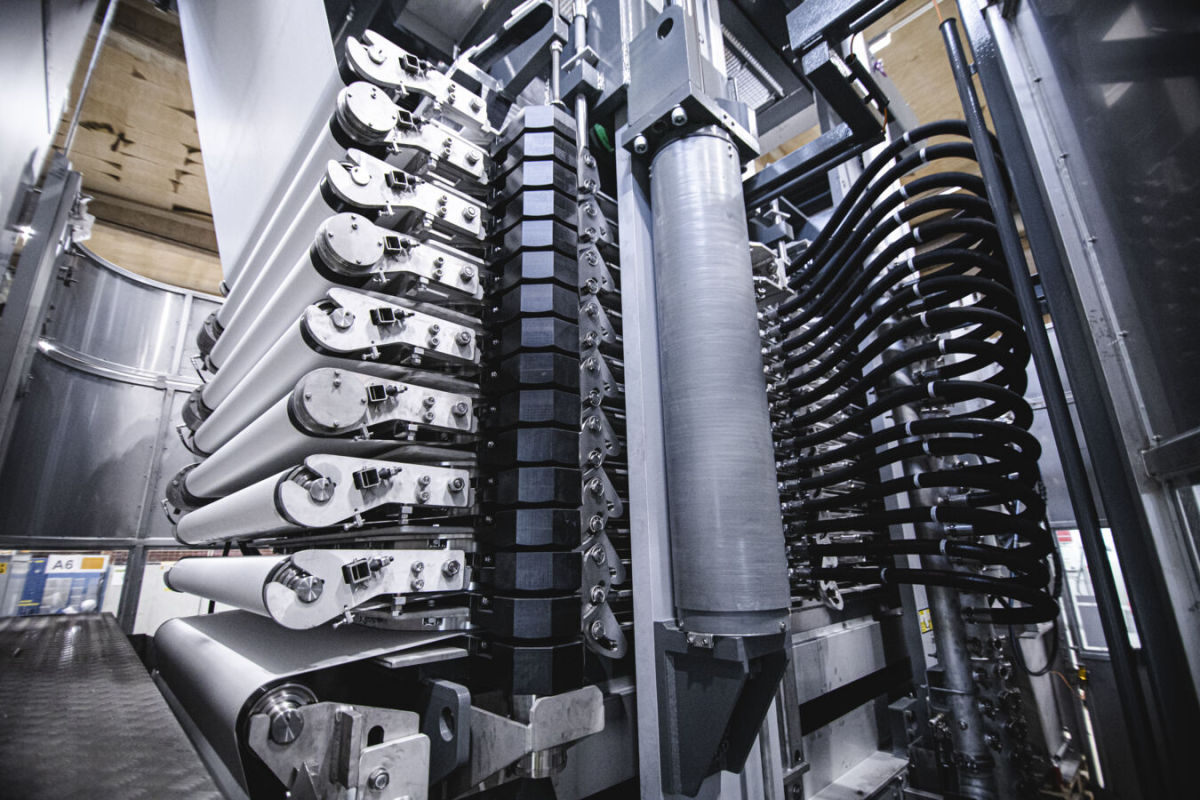

© Metso Outotec

As an OEM supplier of sophisticated equipment, parts and services to the mining industry, Metso Outotec is committed to helping customers maintain their critical assets and to help them take a preventive approach to maintenance.

“Filtration Inspections have the advantage of not only discovering issues that require immediate attention, but also allow for the identification of possible upcoming larger filtration failures or upgrade opportunities. It gives us the chance to proactively respond to our customers and put in place a service plan to address longer-term problems, potentially saving them significant costs in terms of lost production,” stated Juho Pylkkö, Director, Field Service Product Development.

The Filter Inspection packages in brief:

1. Filter Visuals and Vitals package provides a quick way for customers to understand their filters overall condition for peace of mind. This package is designed as a filter quick health check, focusing on rapidly determining the filter’s condition while minimizing downtime required for the inspection.

2. Filter Mechanical Verification package is a standard level inspection with adjustments and fixes, guaranteeing improvement to the filter’s overall availability. This package includes all items from the Visuals and Vitals package plus an OEM inspection with guards and covers removed.

3. Filter Customized Inspection package includes all elements from visual and vitals and mechanical verification programs. This package involves a complete inspection and e.g. measurement of the filters hydraulics and optional system flushing or inventory audits to determine spare parts requirements, are also provided with this program.