Analysis of vibrating machines

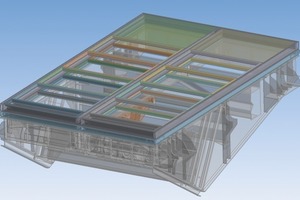

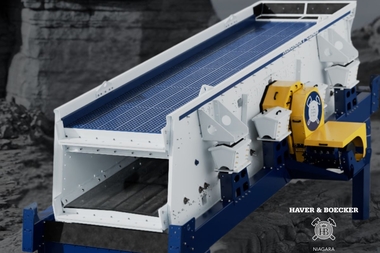

RHEWUM GmbH supports customers which are working on applications in the field of vibration technology in dimensioning, construction, installation and operation of vibrating machines. In the process the company uses its in more than six decades gained experience in construction and manufacturing of high dynamic screening machines in combination with latest computerised simulation (Fig.). RHEWUM supports raw material processing companies as well as machine manufacturers in concept determination and machine design by forecasting the static and dynamic characteristics of components and complete machines. Furthermore offers the company the analysis of steel structures and/or floors of existing or planned buildings regarding its suitability as installation location for vibrating machines. Using mathematical machine analysis the customers are supported in evaluation of machines as well causal research and solving dynamic problems during operation.

Besides the investigation of the existing general conditions on site the special applications are simulated in the company’s system short term. Advanced simulation tools simulate the characteristics of the customer’s machine resp. components after specifying the basic conditions. As result the customer gets an extensive analysis of the load on the machine components and therewith a reliable identification of possible weak spots. To gain a quickest possible response time behaviour of the simulation the software works simultaneously on eight Intel processors using 96 GByte RAM. This equipment ensures a short term and realistic solution even of challenging vibration analysis problems.

RHEWUM uses with ANSYS a powerful finite element program for modelling of coupled physical problems. It works in the field of structural mechanics and thermal tasks. In the field of structural mechanics with ANSYS it is possible to get extensive physical models, such as linear analysis, geometric nonlinearities, nonlinearic material laws, contact analysis, static or transient. ANSYS bases upon latest solver technology in combination with pre- and port-processing. The modular conception of the software combines the advantages of structured and unstructured calculating meshes and is characterised by exact physical models, a robust algorithm and effective parallel processing. The automatic generation of the meshes and the optimal connection to all established CAD-systems (SolidWorks) offer the simple handling of complex geometries.

RHEWUM GmbH, Remscheid (D),

Tel.: +49 2191-5767-0, www.rhewum.com