Continuous filter bed cleaning with the Leiblein FlowSand filter

As an upwards flowing filter, Leiblein’s new FlowSand filter cannot only retain very fine particles from the feed medium on its sand filter, thanks to the simultaneous continuous filter bed cleaning, it doesn’t require any collection basins, rinsing pumps, buffer tanks or complex backwash technology.

Operating principle of continuous filtration

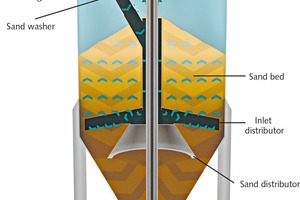

By means of pipes and distributors, the raw water flows into the sand filter bed of the spatial filter standing on a conical tip (Fig. 1). Depending on requirements, this structure is made of steel or concrete. In an upward flow, the water runs through the filter bed from bottom to top being filtrated by the downwards moving filter bed (in countercurrent flow). The filtered water exits the sand filter via an overflow edge to the filtrate outlet. Crucial for a filtering process based on a circulation concept, that is without special storage or cleaning modules, is that the contaminated sand is passed by means of an airlift pump into the upper calming unit. From there, the sand falls into the sand washer, where it is cleaned in a countercurrent flow by a partial flow of the filtrate. The cleaned sand falls back onto the surface of the filter bed via a sand distributor conus, which ensures an even distribution of the sand over the whole filter area. The filter medium practically renews itself each time.

The FlowSand filter for high efficiency

Besides the spectrum of continuous filtration with filter bed self-cleaning, other interesting performance features result for the user. For instance, the use of media with a high solids load is possible. Despite a high solids load, according to the manufacturer, a steady filtrate quality can be obtained. Both feeding by pumps and in free inflow increases adaptability to specific conditions. As the filter does not require any moving mechanical parts, this results in a long lifetime and high availability. On top of this come the simple assembly, the prospect of low energy costs to operate the Leiblein FlowSand filter. Users who want to filter suspensions (Fig. 2) also have the possibility to separate smaller particles or dissolved materials with the addition of flocculants. With the formation of a biofilm, other applications can be opened up.

//www.leiblein.de" target="_blank" >www.leiblein.de:www.leiblein.de