WÖHWA ECS21 energy controlling system

Clear to every operator of mineral processing plants is that now and in the future energy costs will become an increasingly important aspect of in cost analysis. In addition, today and with certainty in the future, regulatory intervention by the government must be expected. The implications become increasingly clear if you consider the electricity tax, EEG levy and the most recent government requirements associated with these in respect of energy management systems in compliance with DIN ISO 50001/DIN 16001.

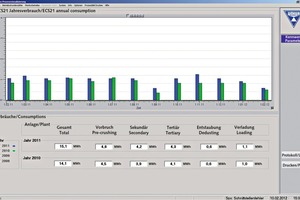

WÖHWA has looked closely at this issue and has developed the ECS21 energy controlling system to give especially the operators of mineral processing plants in the quarrying industry the possibility of continuously recording and analysing all the important electrical consumption data easily and cheaply. In the development of the WÖHWA ECS21 energy controlling system, one particular priority was to ensure that the display of the different consumption levels is clear and easy to analyse. In addition, special attention was paid that the flood of the data does not overwhelm the user of the system (energy manager) in order to make a fast and simple evaluation is possible. The aim of the ESC21 system is to provide the user with a low-cost facility to cumulatively record and, if required, compare all consumption data of the plant components he needs to identify any potential for saving energy in his plant (Fig.). In an additional expansion phase, an option is available to monitor individual machines, such as crushers, screens, belt conveyors, dryers, fans, pumps, etc. to analyse the consumption levels of this equipment.

The system is configured such that the material streams recorded with belt weighers in the different parts of the plant can be analysed and appropriate parameters automatically generated from these results, so that the operator can quickly and easily ascertain whether the consumption levels of the individual plant components/machines are within the set range. In addition, a benchmarking option is possible. That means that the user has the possibility to individually set a minimum or maximum consumption level/material volume flow. If the plant component or machine goes above or below this limit, then the ECS21 automatically signals this deviation to the user so that he can respond immediately.

A conformity certificate of the TÜV Rheinland (Technical Control Board) gives the operator the assurance that the ECS21 system from WÖHWA can be used without any problem in the certification of an energy management system in compliance with DIN ISO 50001 and DIN 16001.