Software for detonation planning

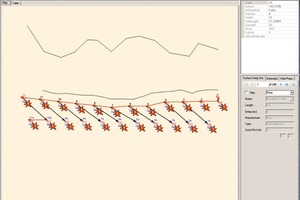

For the first time, detonation planning software is now available on the German market. With QuarryDetonator, electronic, electrical and non-electrical detonators and detonation times can be simulated and tested for overlapping: QuarryDetonator automatically checks the fuse lengths and overlapping times in accordance with specifications. Any compilation of detonators and detonating relays can be simulated. Naturally, boreholes can be deleted or shifted, lengths, angles and detonators can be accessed or surface detonating relays can be modified at any time. Optimal detonation planning can be very quickly completed on the computer. For each blasting (Fig. 1), QuarryDetonator automatically outputs equipment lists, protocols, detonation and drilling plans. Printed out, they can be used directly in the quarry as operating instructions and for checking purposes (Fig. 2).

QuarryDetonator contains data for all common detonators and detonating relays. A wide range of detonator combinations are simply clicked together and immediately simulated and tested. The iron rule that there is no second chance in blasting is therefore a thing of the past. With QuarryDetonator, the so far time-consuming and complicated documentation can be generated at a push of a button. Basic data, such as quarrying and blasting licences, are input once and accessed again and again. Not only the obligatory documentation is completed at practically no expense, transparency is increased within the operation. Every blasting can be simulated with uniform data. Potential for optimization is tapped almost automatically.

The QuarryDetonator detonation software can be used as stand-alone software. But it can also be seamlessly integrated in the Quarry6 detonation planning software from geo-konzept. This can be used to further optimize blasting results. With the 3D laser measurement of the quarry walls, drilling line and borehole positions can planned and checked more precisely than ever before. Boring angle, boring depth, boring direction, underboring as well as other requirements can be planned simply and efficiently on the basis of precise data. Every blasting is not only safer but much more efficient.

geo-konzept GmbH, Adelschlag (D),

Tel.: +49 8424 89890, www.geo-konzept.de